English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

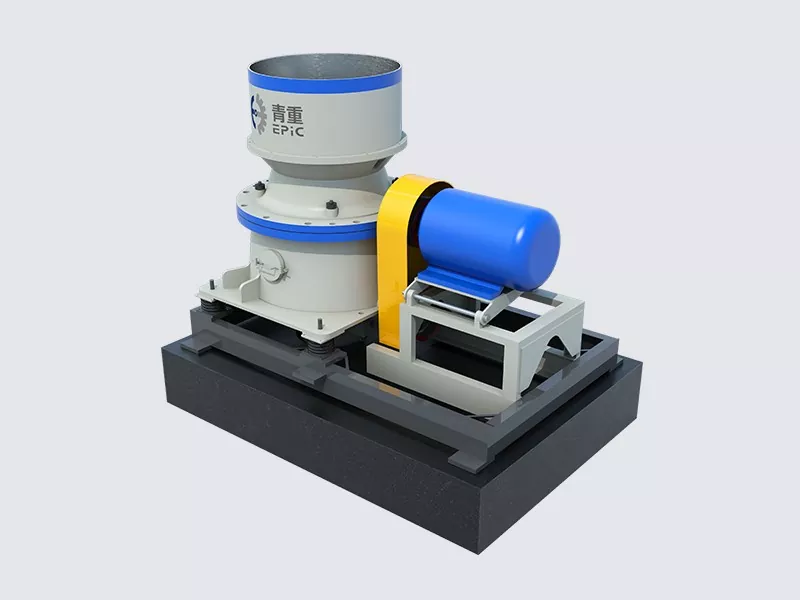

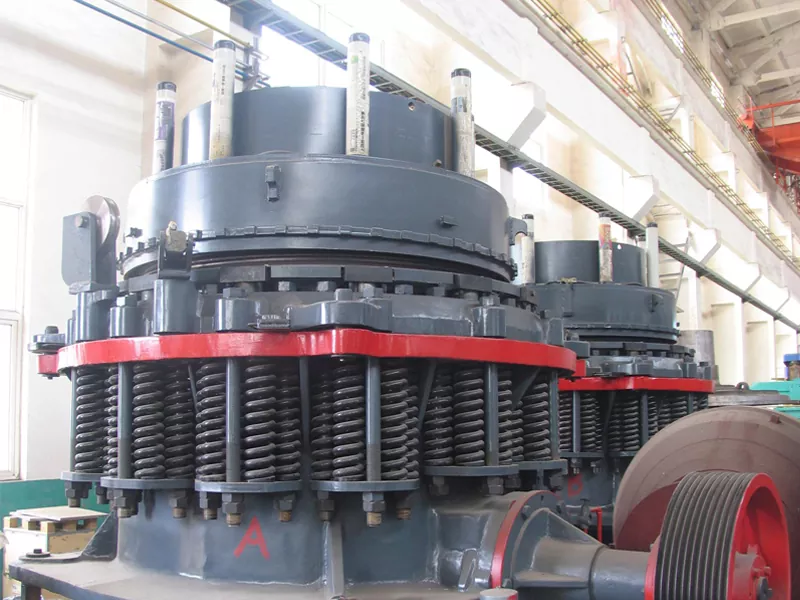

Single Cylinder Hydraulic Cone Crusher

Send Inquiry

Welcome to buy Single Cylinder Hydraulic Cone Crusher from us, every request from customers is being replied within 24 hours. EPIC is the professional manufacturer, we would like to provide you Single Cylinder Hydraulic Cone Crusher and we will offer you the best after-sale service and timely delivery. Single-cylinder hydraulic cone crusher is developed with the world's most advanced crushing technology,integratingmechanical,hydraulic,electrical and intelligent control technologies.The new crusher structure,optimized laminatedcrushing chamber type and intelligent automatic control system make the single-cylinder hydraulic cone crusher havethe incomparable performance characteristics of traditional cone crusher,and can be widely used in medium crushing,fne crushing and ultra-fine crushing operations.

Equipment features:

1.Simple structure,strong reliability,easy maintenance and low operation cost.

2.Large production capacity,high crushing efficiency and low energy consumption.

3.The design concept of constant cavity type makes the lining plate have the longest service life.

4.The rolling mortar walldoes not need filler,so it is fast and convenient to replace.

5.The automatic control system of PLC+touch screen ensures the safe operation of the equipment.

Product Parameter

| Model | Cavity type |

Size of feeding port (mm) |

Minimum discharge port size (mm) |

processing capacity (th) |

Maximum installed power (kw) |

Overall dimension (mm) |

| LMG90 | S1(Extra coarse) | 240 | 22 | 85-170 | 90 | 1550×1575×2545 |

| S2(Medium coarse) | 200 | 19 | 70-130 | |||

| H1(Fine) | 135 | 10 | 45-115 | 1550×1575×1965 | ||

| H2(Medium fine) | 65 | 8 | 35-80 | |||

| H3(Extra fine) | 35 | 4 | 27-60 | |||

| LMG160 | S1(Extra coarse) | 360 | 25 | 120-345 | 160 | 1875×1920×3195 |

| S2(Medium coarse) | 300 | 22 | 105-305 | |||

| S3(Coarse) | 235 | 19 | 90-275 | |||

| H1(Fine) | 185 | 13 | 66-210 | 1875×1920×2400 | ||

| H2(Medium fine) | 90 | 10 | 65-165 | |||

| H3(Extra fine) | 50 | 6 | 48-105 | |||

| LMG250 | S1(Extra coarse) | 450 | 35 | 255-605 | 250 | 2100×2320×4096 |

| S2(Medium coarse) | 400 | 29 | 215-515 | |||

| S3(Coarse) | 300 | 25 | 190-490 | |||

| H1(Fine) | 215 | 16 | 110-395 | 2100×2320×2780 | ||

| H2(Medium fine) | 110 | 13 | 115-340 | |||

| H3(Extra fine) | 70 | 8 | 90-255 | |||

| LMG315 | S1(Extra coarse) | 560 | 41 | 335-1050 | 315 | 2380×2735×4630 |

| D2(Medium coarse) | 500 | 38 | 305-895 | |||

| H1(Fine) | 275 | 16 | 170-665 | 2380×2735×3265 | ||

| H2(Medium fine) | 135 | 16 | 190-505 | |||

| H3(Extra fine) | 65 | 13 | 205-320 | |||

| LMG450 | S1(Extra coarse) | 560 | 54 | 500-1300 | 450 | 2906×3187×4582 |

| S2(Medium coarse) | 465 | 51 | 450-1200 | |||

| LMG560 | H1(Fine) | 300 | 22 | 430-1515 | 560 | 3780×2341×4531 |

| H2(Medium fine) | 155 | 19 | 380-1375 | |||

| H3(Extra fine) | 80 | 10 | 270-775 | |||

| LMG750 | H1(Fine) | 370 | 25 | 460-2130 | 750 | 3100×3623×5305 |

| H2(Medium fine) | 195 | 22 | 525-1605 | |||

| H3(Extra fine) | 85 | 10 | 350-885 |