English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

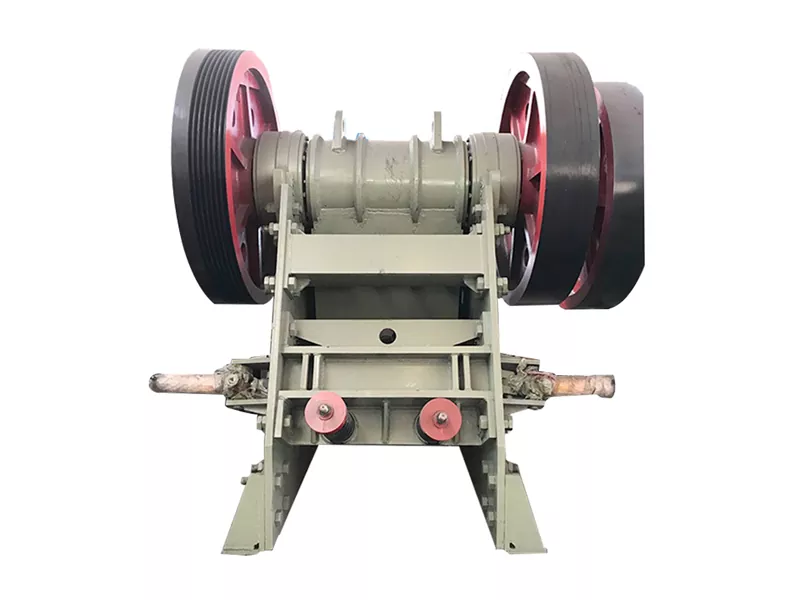

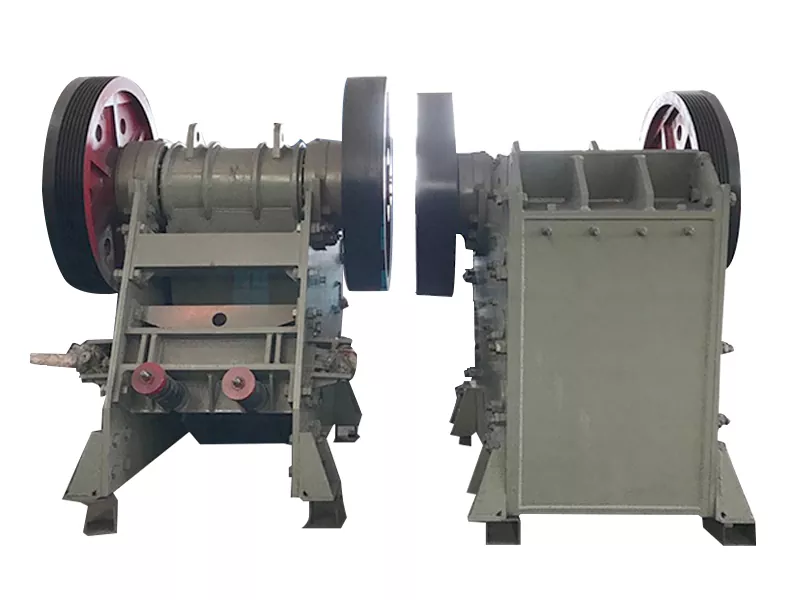

Jaw Crusher

Send Inquiry

Jaw crusher is an early crushing equipment. It is still widely used in metallurgy, chemical industry, building materials, electric power, transportation and other industrial sectors for coarse, medium and fine crushing of various ores and rocks with compressive strength of 147-245MPa due to its simple structure, firmness, reliable operation, easy maintenance and overhaul, and relatively low production and construction costs. In recent years, our factory has specially developed a powerful jaw crusher to meet the needs of metallurgy, mining, construction and other industrial sectors for crushing high-strength and high-hardness micro-carbon ferrochrome.

Jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials, and is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive strength of the crushed material is 320MPa.

[Feed particle size]: 120-1500mm

[Production capacity]: 1-2200t/h

[Application range]: metallurgy, chemical industry, building materials, electric power, transportation and other industrial sectors. 【Product Introduction】: Jaw crusher is a common crushing equipment in mining crushing production. The maximum compressive strength of the jaw crusher we produce is 320MPa, which can meet the crushing and processing of various materials.

Advantages and characteristics

1. Deep cavity crushing, high efficiency and energy saving

Optimized deep cavity crushing, no dead zone, greatly improved feeding and crushing efficiency, single machine energy saving 15%-30%, system energy saving more than doubled.

2. Strong bearing capacity and high stability Larger forging billets process heavy eccentric shafts, high manganese steel jaw plates and high-grade cast steel movable jaw assemblies, the equipment has stronger bearing capacity and higher stability.

3. Advanced technology and long service life

Learning from the world's advanced manufacturing technology, digital analysis of the operation of each component, precise internal structure, and greatly extended equipment service life.

Working principle

The jaw crusher is a curved extrusion type, and its operating principle mainly simulates the movement of the two jaws of animals. During operation, the motor drives the belt and pulley to move the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw increases, thereby pushing the movable jaw plate close to the fixed jaw plate. The material is crushed multiple times through squeezing, rubbing, and grinding between the two jaw plates; when the movable jaw descends, the angle between the toggle plate and the movable jaw decreases, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. The crushed material is freely discharged through the discharge port at the bottom of the jaw cavity under the action of gravity. With the continuous rotation of the motor, the movable jaw performs periodic crushing and discharging to achieve mass production.

The jaw crusher is mainly composed of a frame, an eccentric shaft, a large pulley, a flywheel, a side guard plate, a toggle plate, a toggle plate back seat, a gap adjustment screw, a reset spring, a fixed jaw plate and a movable jaw plate, among which the toggle plate also plays a role of insurance.

PE series and PEX series jaw crusher are crusher equipment with high production capacity,large crushing ratio and high crushing efficiency.The main working parts ofthe crusher are composed of fixed jaw and movable jaw.The movable jaw performs

periodic reciprocating movement on the fixed jaw,and the material is crushed between the two jaw.

It is suitable for coarse,medium broken hard materials and medium hard materials.During operation,the motor drivesthe eccentric shaft to rotate through the belt puley to make the movable jaw periodically close to and leave the fixedaw,so as to crush,rub,grind and other multiple crushing of the material,so that the material changes from large tosmall,and gradually falls unti t is discharged from the outlet.

The jaw crusher is widely used in metallurgical mines,building materials,silicate and chemical industries.It is generally used for coarse and medium crushing of hard or medium hard ores in the production of mineral processing industry.

Product Parameter

| Model |

Demesion of import (mm) |

Max.feeding size (mm) |

Adjusting range of discharging outlet (mm) |

Power (kw) |

Capacity (t/h) |

Demension of outline LxWxH (mm) |

| PE Series | ||||||

| PE100×150 | 100×150 | 80 | 5~20 | 2.2 | 0.5~2 | 525×535×605 |

| PE150×250 | 150×250 | 125 | 10~40 | 5.5 | 2~6 | 875×745×935 |

| PE200×350 | 200×350 | 160 | 10~50 | 7.5 | 6~10 | 1080×1060×1088 |

| PE250×400 | 250×400 | 210 | 20~60 | 15 | 8~16 | 1108×1090×1392 |

| PE250×500 | 250×500 | 210 | 20~80 | 18.5 | 13~21 | 1360×1450×1440 |

| PE400×600 | 400×600 | 350 | 40~100 | 30 | 14~36 | 1650×1748×1520 |

| PE500×750 | 500×750 | 425 | 50~100 | 55 | 45~80 | 1892×2054×1853 |

| PE600×900 | 600×900 | 500 | 65~160 | 55-75 | 70~120 | 2520×1840×2303 |

| PE750×1060 | 750×1060 | 630 | 80~140 | 110 | 130~260 | 2620×2302×3110 |

| PE900×1200 | 900×1200 | 750 | 95~165 | 110 | 220~380 | 3789×2826×3025 |

| PE1000×1200 | 1000×1200 | 850 | 195~265 | 110 | 230~380 | 3889×2826×3025 |

| PE1200×1500 | 1200×1500 | 1020 | 150~300 | 200 | 400~800 | 4200×3750×3820 |

| PEX Series | ||||||

| PEX250×1000 | 250×1000 | 210 | 25~60 | 30-37 | 15-50 | 1964×1550×1380 |

| PEX250×1200 | 250×1200 | 210 | 25~60 | 37-45 | 20-60 | 2192×1605×1415 |

| PEX300×1300 | 300×1300 | 250 | 25~105 | 55-75 | 20-90 | 1777×2330×1740 |

| PEX400×1200 | 400×1200 | 320 | 35~95 | 45-55 | 28-95 | 2256×2100×1960 |