English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Impact Crusher

Send Inquiry

Impact crusher (impact crusher) is mainly used in metallurgy, mining, cement, chemical industry, refractory materials and ceramics and other industrial sectors, as well as highway construction, water conservancy projects, building gravel, machine-made sand processing and other fields.

[Feed particle size]: 300-700mm

[Production capacity]: 30-550t/h

[Application range]: various ore crushing, railways, highways, energy, cement, chemical industry, construction and other industries.

[Product introduction]: This series of impact crushers can process materials with a side length of 100-500 mm or less. Its compressive strength can reach up to 350 MPa. It has the advantages of large crushing ratio and cubic particles after crushing. It is suitable for crushing medium-hard materials. The discharge particle size can be adjusted and the crushing specifications are diversified.

Advantages and characteristics

1. Large feed inlet, high crushing chamber, high hardness of adapted materials, large block size, and less stone powder in the product.

2. The gap between the impact plate and the hammer can be easily adjusted to effectively control the discharge particle size and good particle shape.

3. Compact structure, strong machine rigidity, and large moment of inertia of the rotor.

4. High chromium plate hammer, impact resistance, wear resistance, and large impact force.

5. Keyless connection, easy maintenance, economical and reliable.

6. Complete crushing function, high productivity, low wear of machine parts, and high comprehensive benefits.

Working principle

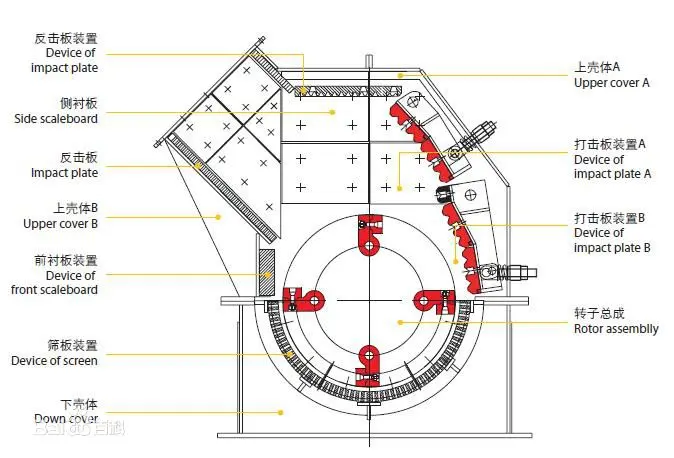

The impact crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at high speed. When the material enters the plate hammer action area, it collides with the plate hammer on the rotor and is crushed. Then it is thrown onto the impact device and crushed again, and then bounces back from the impact lining to the plate hammer action area and crushed again. This process is repeated, and the material enters the first, second, third, and counterattack chambers from large to small and is repeatedly crushed until the material is crushed to the required particle size and discharged from the discharge port. Adjusting the gap between the impact frame and the rotor can achieve the purpose of changing the material discharge particle size and material shape.

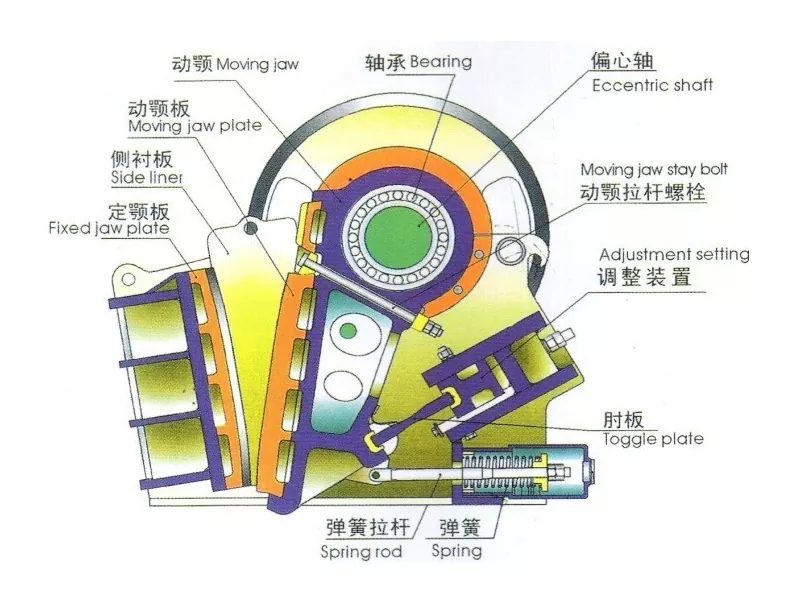

The structure is simple and consists of a casing, a rotor and an impact plate. The main working part of the impact crusher is a high-speed rotating rotor with a plate hammer. During the reciprocating impact process, the material blocks also collide with each other. As the material is hit by the plate hammer, the impact of the impact plate and the collision between each other, cracks and loosening are constantly generated inside, which eventually leads to crushing. The impact device is used to withstand the material hit by the plate hammer and rebound it out. The main component is the impact plate, which is welded with steel plates. There are wear-resistant linings on its impact surface, and some use impact bars or grating plates.

Technical parameters of secondary and tertiary impact crushers

| Model |

Feed size (mm) |

Motor power (kw) |

Productive power (t/h) |

Overall dimension W×D×H(mm) |

| Cl1110 | 250 | 160 | 60-210 | 2826×2087×2285 |

| Cl1213 | 300 | 200 | 80-280 | 2903×2530×2411 |

| Cl1316 | 300 | 250 | 100-350 | 3320×2770×2535 |

| Cl1521 | 350 | 2x(200-250) | 200-600 | 3450×3620×2770 |

Primary impact crusher parameters

| Model |

Feed size (mm) |

Motor power (kw) |

Productive power (t/h) |

Overall dimension W×D×H(mm) |

| Cl1313 | 600 | 200 | 100-480 | 2972×2560×2937 |

| Cl1415 | 600 | 250 | 120-600 | 2985×2790×3068 |

| Cl1620 | 800 | 2x(200-250) | 220-900 | 4261×3480×3780 |

| Cl2023 | 800 | 2x500 | 400-2000 | 5151×4424×4712 |