English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

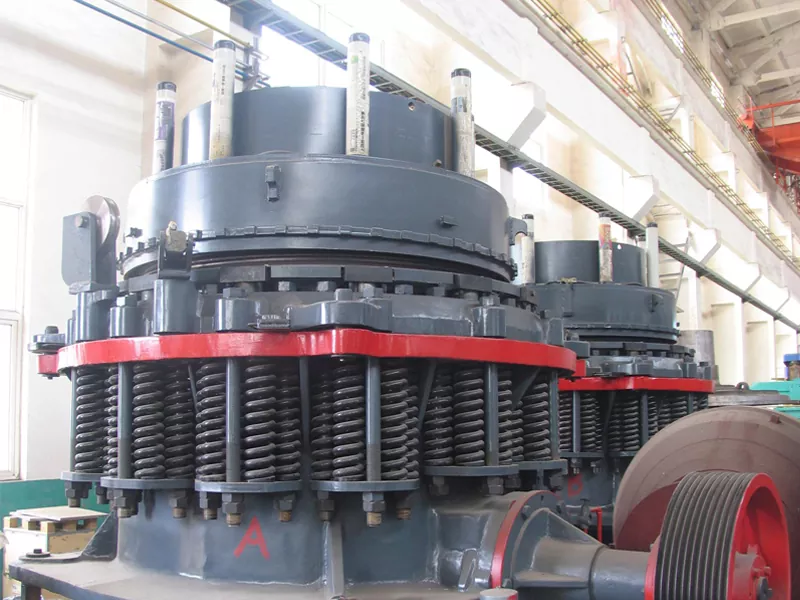

Hammer Crusher

Send Inquiry

Hammer crusher, also known as hammer crusher, is suitable for crushing medium hardness and brittle materials in mining, cement, coal, metallurgy, building materials, highway, fuel and other industries.

The hammer crusher consists of a box, a rotor, a hammer head, an impact liner, a screen plate, etc. The equipment can adjust the grate gap according to user requirements and change the discharge particle size to meet the different needs of different users.

[Feed particle size]: ≤200-≤350mm

[Production capacity]: 5-150m³/h

[Motor power]: 11-480kw

[Product introduction]: The hammer crusher is used to crush various medium-hard and weakly abrasive materials, the compressive strength of which does not exceed 100MPa and the moisture content is less than 15%. It is also used to crush broken wood and paper with strong fiber structure, elasticity and toughness.

Advantages and characteristics

1. The working hammer head is cast using a new process and is wear-resistant and impact-resistant.

2. The required particle size can be adjusted according to customer requirements.

3. The hammer crusher body structure is sealed, which solves the dust pollution and ash leakage problems in the crushing workshop.

4. The overall design has beautiful shape, compact structure, few wearing parts, and convenient maintenance. It is an upgraded product.

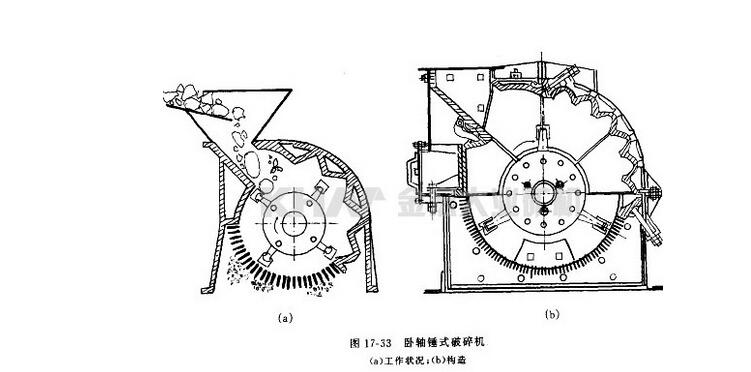

Working principle

The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feeding port and crushed by the impact, impact, shearing and grinding of the high-speed hammer. At the bottom of the rotor, there is a screen plate. The particle size smaller than the screen hole size in the crushed material is discharged through the screen plate, and the coarse particle size larger than the screen hole size is retained on the screen plate and continues to be hit and ground by the hammer, and finally discharged out of the machine through the screen plate.

Product Parameter

|

Models |

Rotor size (mm) |

Feed size (mm) |

Discharge size (mm) |

Motor power (kw) |

Production capacity (t/h) |

Weight (Kg) |

|

PFY0807 |

Φ850*700 |

40-150 |

≤25占85% |

30-55 |

15-30 |

≤8900 |

|

PFY1007 |

Φ1000*700 |

50-200 |

≤25占85% |

37-90 |

25-60 |

≤10500 |

|

PFY1010 |

Φ1000*1000 |

60-250 |

≤25占85% |

55-110 |

30-100 |

≤13900 |

|

PFY1013 |

Φ1000*1300 |

80-250 |

≤25占85% |

110-185 |

50-120 |

≤14500 |

|

PFY1210 |

Φ1210*1000 |

100-300 |

≤25占85% |

110-185 |

60-140 |

≤16000 |

|

PFY1212 |

Φ1200*1200 |

100-300 |

≤25占85% |

132-185 |

80-160 |

≤21000 |

|

PFY1214 |

Φ1200*1200 |

120-300 |

≤25占85% |

132*200 |

80-180 |

≤21500 |

|

PFY1310 |

Φ1300*1300 |

120-300 |

≤25占85% |

132*200 |

70-150 |

≤19000 |

|

PFY1315 |

Φ1300*1500 |

150-300 |

≤25占85% |

180-315 |

100-250 |

≤23000 |

|

PFY1320 |

Φ1300*2000 |

150-350 |

≤25占85% |

300-400 |

200-350 |

≤26000 |

|

PFY1415 |

Φ1400*1500 |

200-400 |

≤25占85% |

300-400 |

250-400 |

≤26000 |

|

PFY1622 |

Φ1600*2200 |

200-400 |

≤25占85% |

450-560 |

400-600 |

≤101000 |

|

PFY1822 |

Φ1800*2200 |

250-500 |

≤25占85% |

560-710 |

500-800 |

≤118000 |