English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

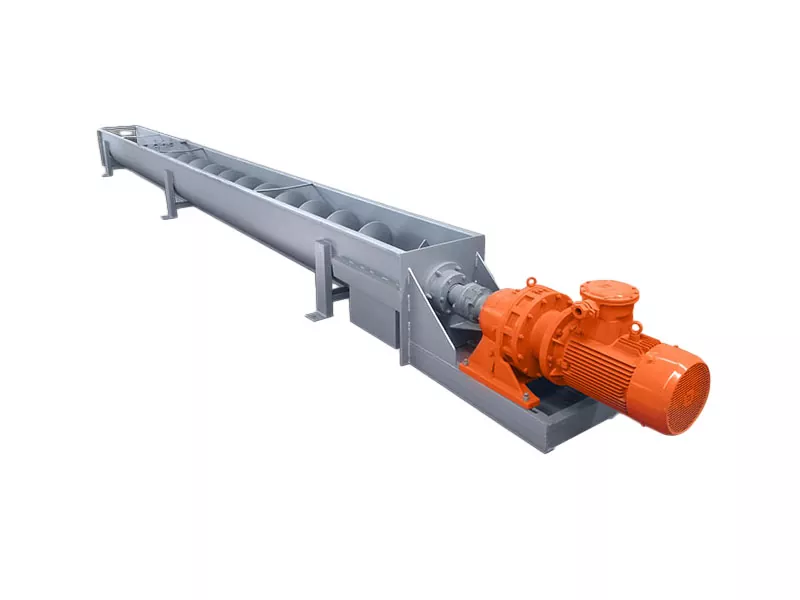

Screw Conveyor

Send Inquiry

By the driving device closed groove box and screw,the spiral rotation of the material in the box is output,so that the material does not rotate with the screw conveyor blade force is the material tself weight and screw conveyor shel friction resistance to the material.

Equipment characteristics

1,simple structure,small cross section size

2,good sealing,reliable work,low manufacturing cost,easy to intermediate loading and unloading,conveying direction can be reversed,but also to the opposite two directions at the same time

3.In the conveying process,the materials can also bestirred,mixed,heated and cooled

4,through the loading and unloading gate can adjust the material flow,but it is not suitable to transport metamorphic, viscous,easy to caking and large materials

5,conveying process of material is easy to break,screw and groove easy to wear

6,the unit power is large,in use to maintain the sealing of the tank and the spiral and the tank between the appropriate gap

Product Parameter

| Model | GX15 | GX20 | GX25 | GX30 | GX40 | GX50 | GX60 |

| Spiral diameter(mm) | 150 | 200 | 250 | 300 | 400 | 500 | 600 |

| Magnesium powder transport capacity(t/h) | 4.5 | 8.5 | 16.5 | 23.3 | 54 | 89 | 139 |

| Cement transport capacity(th) | 4.1 | 7.9 | 15.6 | 21.2 | 51 | 85 | 134 |

| Soda ash transport capacity(th) | 3 | 6.7 | 10.7 | 18 | 35.5 | 70 | 97 |

| Width ×height(mm) | 272×314 | 342×384 | 392×464 | 468×555 | 572×685 | 706×823 | 806×973 |

| Minimum arrangement of feed port(mm) | 190 | 220 | 270 | 300 | 350 | 450 | 550 |

| Feed port square port size(mm) | 170 | 220 | 270 | 320 | 420 | 528 | 628 |

| Feed port height(mm) | 75 | 100 | 120 | 140 | 160 | 160 | 180 |

| Discharge port square port size(mm) | 176 | 226 | 276 | 328 | 428 | 536 | 636 |

| Discharge port height(mm) | 135 | 165 | 195 | 225 | 280 | 340 | 430 |