English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

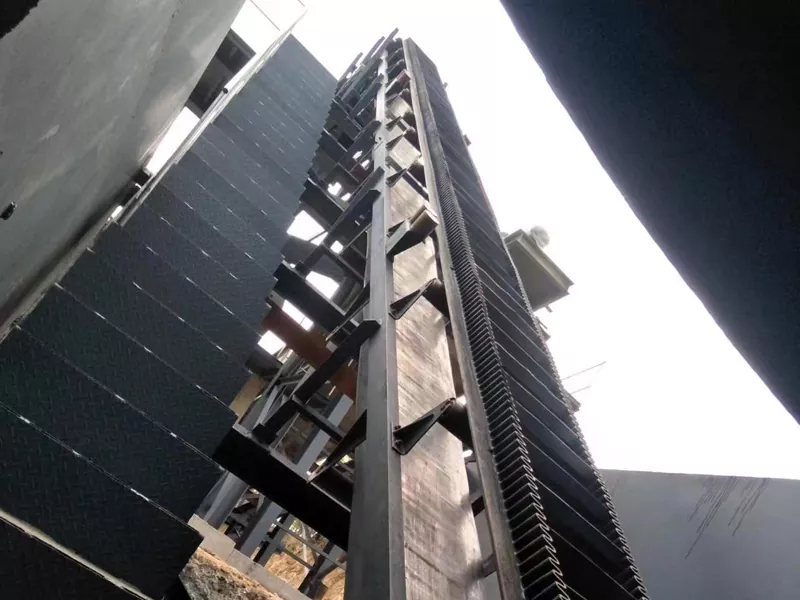

Bucket Elevator

Send Inquiry

Bucket elevator (one) D type,HL type bucket elevator

D type bucket elevator code for D,that is,belt bucket elevator;Product specifications are expressed in bucket width. Compared with the chain ring chain bucket elevator,the liting machine has many specifications,large throughput,high lifing height,stable and reliable operation,long life and other significant advantages.The elevator for centrifugal or mixed discharge,cut type charging.It is suitable for vertical conveying loose density of 1.5t/m3 powder,granular,and smallblock of smalgrinding and absorption loose material,such as grain,coal,cement,crushed ore,etc.,the highest lifting height,the material temperature does not exceed 60℃ .

HL type bucket elevator is suitable for vertical transportation of large grinding cut powder,granular,and small block materials,such as grain,coal,cement,crushed ore,conveying the highest height of 40m,its characteristics are,simple structure,smooth operation,cut type loading,mixed or gravity discharge,the rim using combination sprocket,easy to replace,sprocket rim by special treatment long life,The lower part of the gravity automatic tensioning device,can maintain a constant tension,avoid slipping or chain off,at the same time when the hopper is blocked,can effectively protect the moving parts,the material temperature does not exceed 250℃ .

Product Parameter

| Model | D160 | D250 | D350 | D450 | HL250 | HL300 | HL400 |

| Material temperature(℃) | (Ordinary belt) | (Ordinary belt) | (Resistant belt) | (Resistant belt) | Higher than D-type machine | Higher than D-type machine | Higher than D-type machine |

| S-bucket conveying capacity(m²h) | 8 | 21.6 | 42 | 70 | 22 | 28 | 47 |

| Q bucket conveying capacity (m>h) | 3.1 | 11.8 | 25 | 48 | 12 | 16 | 30 |

| Maximum bulk size of material(mm) | 25 | 35 | 45 | 55 | 35 | 40 | 50 |

| Minimum motor power(kW) | 2.2 | 3 | 5.5 | 7.5 | 4 | 5.5 | 5.5 |

| Maximum motor power(kW) | 7.5 | 7.5 | 10 | 10 | 7.5 | 10 | 10 |

| Minimum height of bucket lifing machine(mm) | 4820 | 4480 | 4300 | 4540 | 4480 | 4660 | 4520 |

| Maximum height of bucket lifting machine(mm) | 30020 | 30080 | 30300 | 29500 | 30080 | 30160 | 30320 |

| Height difference(mm) | 300 | 400 | 500 | 640 | 400 | 500 | 600 |

| Tension drum center height(mm) | 530 | 620 | 650 | 800 | 620 | 650 | 800 |

| Driving section housing height (mm) | 453 | 503 | 550 | 650 | 503 | 600 | 654 |

| 45°feed port height(mm) | 1050 | 1250 | 1440 | 1630 | 1250 | 1300 | 1630 |

| 60°feed port height(mm) | 1310 | 1540 | 1770 | 2000 | 1540 | 2280 | 2670 |

| 45°depth of discharge port(mm) | 800 | 900 | 1100 | 1200 | 900 | 1120 | 1200 |

| Depth of horizontal discharge port(mm) | 855 | 960 | 1170 | 1800 | 960 | 1190 | 1280 |

| Dimensions of side housing(mm) | 456 | 586 | 710 | 858 | 568 | 638 | 758 |

| End casing ruler(mm) | 906 | 1106 | 1236 | 1458 | 1106 | 1338 | 1458 |

| Maximum side size of driving position(mm) | 1060×293 | 1361×365 | 1521×423 | 1682×486 | 1361×365 | 1512×401 | 1632×461 |

| Maximum size of end face of driving part(mm) | 906×800 | 1281×936 | 1358×1122 | 1470×1303 | 1281×936 | 1362×1172 | 1470×1294 |

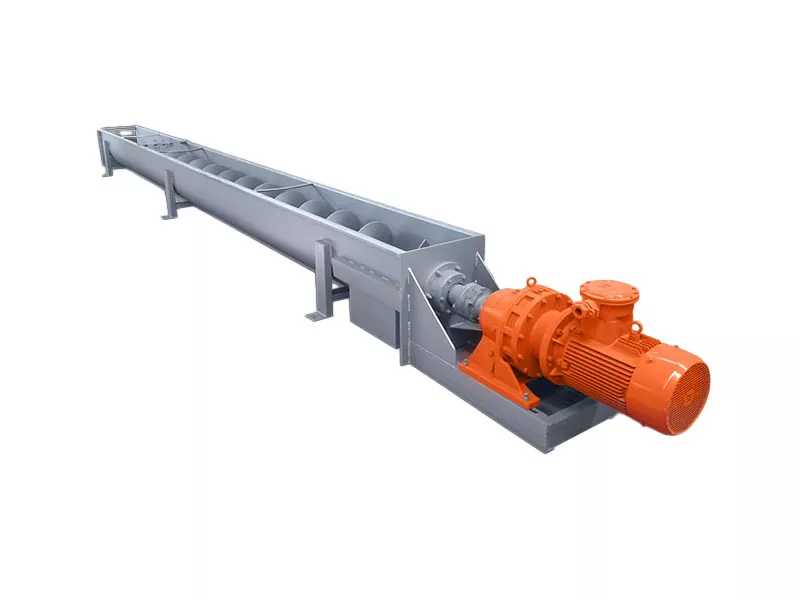

Bucket elevator (two) D type,TH series bucket elevator

The hopper scoops the material from the storage below,and as the conveyor belt or chain is lifed to the top,it turns downward after bypassing the jacking wheel,and the bucket elevator tits the material into the receiving slot.Belt drive bucket elevator belt with rubber belt,installed in the next or above the transmission drum and the upper and lower side of the drum,chain drive bucket elevator is generally equipped with two parallel transmission chain,on or below a pair of drive sprocket,under or above is a pair of change sprocket,bucket elevator is equipped with housing,to prevent the dust in the bucket elevator.

Equipment characteristics

1,TH type is a kind of ring chain bucket elevator using mixed or gravity discharge,excavating type charging:

2,traction parts with high quality alloy steel ring chain,the middle housing is divided into single,double channel two forms for the machine weight box constant force automatic tensioning,sprocket can be changed rim combined structure;

3,long service life,easy to replace the rim;

4,the lower part of the gravity automatic tensioning device,can maintain a constant tension,avoid slipping or chain off, at the same time when the hopper encountered accidental factors caused by the phenomenon of clamping has a certain tolerance,can effectively protect the lower shaft and other components

Product Parameter

| Model | TH315 | TH400 | TH500 | TH630 | TH800 | TH1000 | |||||||

| Bucket type(m³/h) | zh | sh | zh | sh | zh | sh | zh | sh | zh | sh | zh | sh | |

| throughput(mm) | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | 146 | 235 | 235 | 365 | |

| Bucket width(mm) | 315 | 400 | 500 | 630 | 800 | 1000 | |||||||

| Hopper |

斗容 Dourong(L) |

3.75 | 6 | 5.9 | 9.5 | 9.3 | 15 | 14.6 | 23.6 | 23.3 | 37.5 | 37.6 | 58 |

| Bucket distance(mm) | 512 | 688 | 920 | ||||||||||

| lameter ×pitch | 18×64 | 22×86 | 26×92 | ||||||||||

| Chain bucket | Ring number | 7 | 7 | 7 | |||||||||

| Number of strips | 2 | 2 | 2 | ||||||||||

| Single root failure load(kN) | >320 | >480 | >570 | ||||||||||

| Sprocket pitch diameter(mm) | 630 | 710 | 600 | 900 | 1000 | 1250 | |||||||

| Hopper running speed(m/s) | 1.1 | 1.5 | 1.6 | ||||||||||

| Spindle revolution(r/min) | 42.5 | 37.6 | 35.8 | 31.8 | 30.5 | 24.4 | |||||||