English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

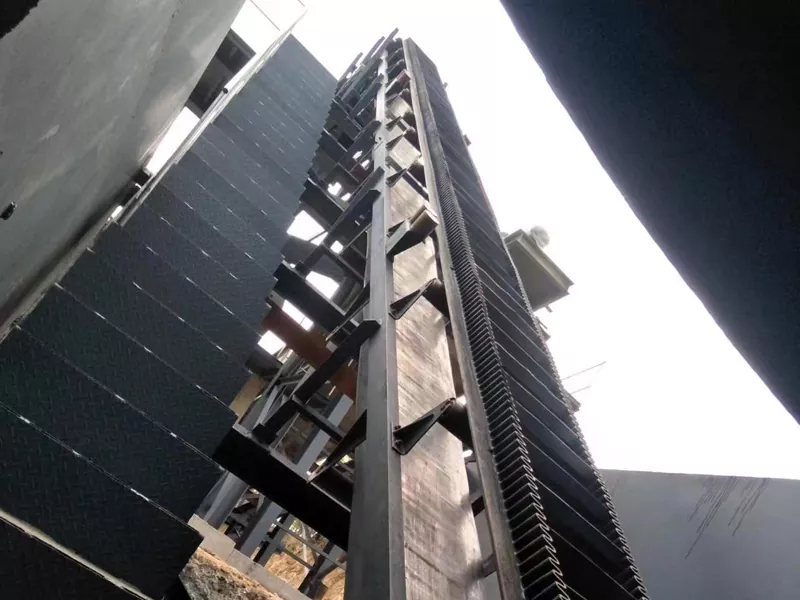

Belt Conveyor

Send Inquiry

TD 75 Belt Conveyor

EPIC is one of leading China Belt Conveyor manufacturer, supplier and exporters. Materials enter from the cold end of the rotary kin,because the kiln body into a certain slope,and continuous rotation,so that raw materials continuously move to the hot end.The fuel is injected from the hot end,burning heat and producing high temperature flue gas under the air combustion,the hot gas is driven by the fan,the flow from the hot end to the cold end,the heat exchange between the material and the flue gas in the process of reverse movement,so that the raw material becomes clinker.

Equipment characteristics

Rotary kiln has simple structure and strong controllability,which is conducive to operation and maintenance.

Product Parameter

| Bearing roller form |

Tape speed (m/s) |

B Bandwidth B(mm) | |||||

| 500 | 650 | 800 | 1000 | 1200 | 1400 | ||

| Q Throughput Q(t/h) | |||||||

| Groove idler | 0.8 | 78 | 131 | - |

一 |

一 |

|

| 1.00 | 97 | 164 | 278 | 435 | 655 | 891 | |

| 1.25 | 122 | 206 | 348 | 544 | 819 | 1115 | |

| 1.6 | 156 | 264 | 445 | 696 | 1048 | 1427 | |

| 2.0 | 191 | 323 | 546 | 853 | 1284 | 1748 | |

| 2.5 | 232 | 391 | 661 | 1033 | 1556 | 2118 | |

| 3.15 | 824 | 1233 | 1858 | 2528 | |||

| 4.0 | 2202 | 2995 | |||||

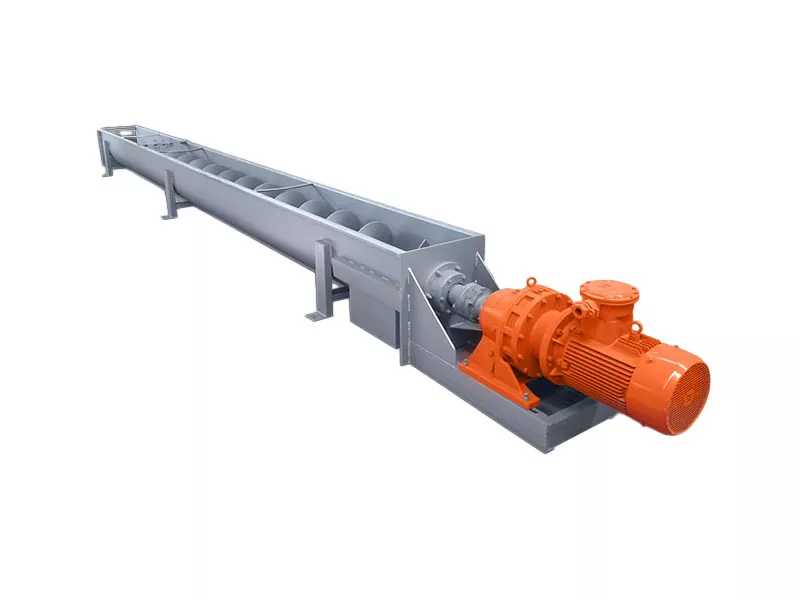

TDT II Belt Conveyor

DTIl belt conveyor is a general series of products,can be widely used in metallurgy,mining,coal,port,power station, building materials,chemical,light industry,petroleum and other industries.By single or multiple units of synthetic transport system to transport materials,can transport loose density of 500-2500 kg/m3 of various loose materials and finished articles.

The working environment temperature of DTIl belt conveyor is generally-25℃to+40℃.The material temperature should not exceed 70℃;Heat-resistant rubber belt can transport high temperature materials below 120℃.The belt conveyor should not be used when the material temperature is higher.When conveying materials with acid and alkaline oil substances and organic solvents,it is necessary to use oil resistant,acid and alkali resistant rubber belt plastic belt. DTII belt conveyors are designed according to component series.Designers can according to the delivery process requirements.According to different terrain,working conditions for selection design and combined into the whole conveyor.This series of parts can meet the requirements of horizontal and inclined transportation,also can be used with convex arc,concave arc segment and linear segment combination of transportation form.

The materia lumpiness allowed by conveyor depends on bandwidth,belt speed,slot Angle and dip Angle.It also depends on how often the bulk material is present.

Product Parameter

| Model | DT IⅡ500 | DT Il 650 | DT |800 | DT IⅡ1000 | DT Ⅱ |1200 | DTIⅡ1400 |

| Bandwidth(mm) | 500 | 650 | 800 | 1000 |

1200 |

1400 |

| Maximum grain size(mm) | 100 | 150 | 200 | 300 | 350 | 350 |

| Tape speed(m/s) | 0.3~1.6 | 0.3~1.6 | 0.3~2.0 | 0.3~2.0 | 0.5~2.5 | 0.5~2.5 |

| Transport capacity(m³h) | 25~138 | 48~254 | 75~396 | 121~810 | 296~1485 | 412~2065 |