English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

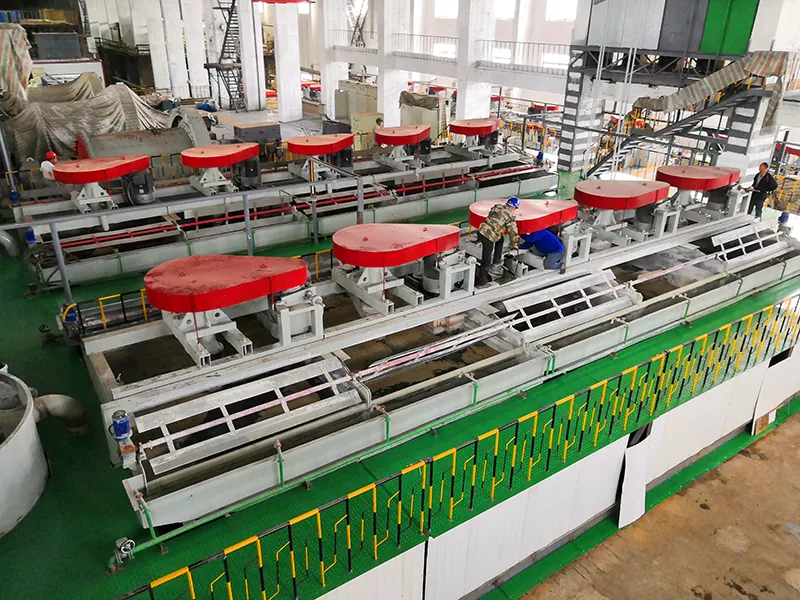

Self-Aspirated Mechanical Flotation Cells For Coarse Granule

Send Inquiry

【Product Introduction】A self-aspirating mechanical stirring flotation unit with slurry suction/non-slurry suction.

【Effective volume】0.15~24m3

【Scope of application】This flotation machine is suitable for the selection of non-ferrous and ferrous metals, and can also be used for the selection of non-metals such as coal fluorite and talc. It is more widely used for the selection of non-ferrous metals such as gold, silver, copper, iron, tungsten, lead, zinc, tin, molybdenum, nickel, tantalum, niobium, manganese ore, coal, etc. It can also be used for the roughing and concentrating of ferrous metals and non-metals.

【Product improvement】BF type flotation machine is divided into type I and type II. Type I is improved with reference to type SF, and type II is improved with reference to type JJF. Type I is a suction slot, and type II is a direct current slot, usually referred to as type BF.

Advantages and characteristics

1. Large air suction volume and low power consumption;

2. Each slot has the triple functions of air suction, slurry suction and flotation, which is called flotation circuit, does not require any auxiliary equipment, horizontal equipment, and is convenient for process changes.

3. Reasonable slurry circulation can minimize the precipitation of coarse sand.

4. Equipped with automatic and electric control devices for the slurry surface, it is easy to adjust.

Working principle

When the impeller rotates, the slurry in the upper and lower impeller chambers generates centrifugal force under the action of the upper and lower blades and is thrown to the surroundings, forming a negative pressure zone in the upper and lower impeller chambers. At the same time, the slurry on the upper part of the cover plate is sucked into the upper impeller chamber through the circulation holes on the cover plate, forming an upper circulation of slurry. When the lower blade throws out the slurry to the surroundings, the slurry at the lower part is replenished to the center, thus forming a lower circulation of slurry. The air is sucked into the upper impeller chamber through the suction pipe and the center tube, mixed with the sucked slurry, forming a large number of fine bubbles, which are evenly dispersed in the trough after steady flow through the cover plate to form mineralized bubbles. The mineralized bubbles float to the foam layer and are scraped out by the scraper to form a foam product.

Product Parameter

| Model |

Volume (m³) |

Tank size (mm) |

Impeller diameter (mm) |

Processing power (m³/min) |

Motor power (kw) |

| BF-2.8 | 2.8 | 1650×1650×1150 | 550 | 1.4-3 | 11/1.5 |

| BF-4 | 4 | 1900×2000×1200 | 650 | 2-4 |

15/1.5 |

| BF-6 | 6 | 2200×2350×1300 | 700 | 3-6 |

18.5/15 |

| BF-8 | 8 | 2250×2850×1400 | 760 | 4-8 |

30/1.5 |

| BF-10 | 10 | 2250×2850×1700 | 760 | 5-10 |

30/1.5 |

| BF-16 | 16 | 2850×3800×1700 | 850 | 8-16 | 37/1.5 |

| BF-20 | 20 | 2850×3800×2000 | 850 | 10-20 | 37/1.5 |

| BF-24 | 24 | 3150×4150×2000 | 920 | 12-24 | 45/1.5 |