English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Rotary Vibrating Screen

Send Inquiry

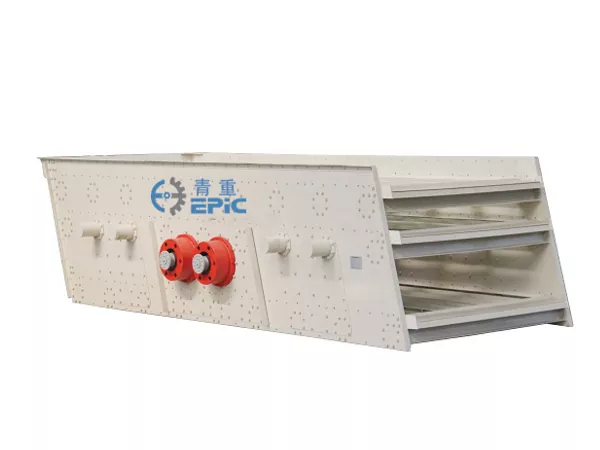

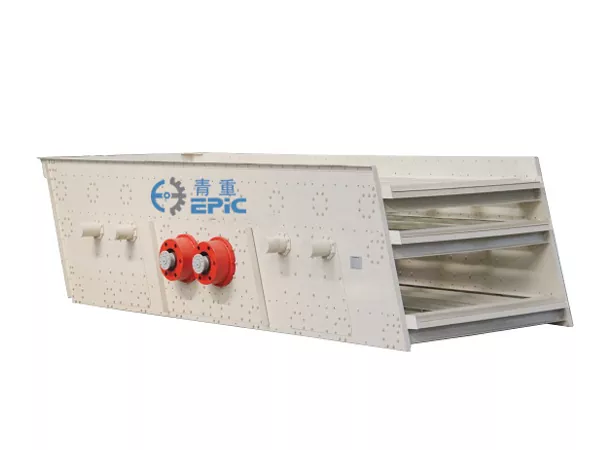

YA round vibrating screen

EPIC is one of the famous China Rotary Vibrating Screen manufacturer and supplier. Our factory specializes in manufacturing of Rotary Vibrating Screen. Every request from customers is being replied within 24 hours.YA series circular vibrating screen The circular vibrating screen is mainly composed of a screen box, a screen mesh, a vibrator and a vibration damping spring. The vibrator is installed on the side plate of the screen box and is driven by the motor through a V-belt to generate centrifugal inertia force, forcing the screen box to vibrate. The vibrating body, i.e. the screen box, moves in an approximate circular motion trajectory. During this period, materials smaller than the screen hole diameter fall through the screen hole to the lower layer and become screen undersize, and materials larger than the screen hole diameter are discharged from the discharge port after continuous jumping motion, and finally the screening work is completed.

Advantages and characteristics

1. The block eccentricity is used as the exciting force, and the exciting force is strong.

2. The screen beam and the screen box are connected by high-strength bolts without welding.

3. The screen machine has a simple structure and is easy and quick to maintain.

4. The tire coupling is used, which is flexible and runs smoothly.

5. The small amplitude, high frequency and large inclination structure make the machine have high screening efficiency, maximum processing, long life, low power consumption and low noise.

Working Principle

The circular vibrating screen machine mainly consists of a screen box, a screen mesh, a vibrator, a vibration damping spring device, a chassis, etc. The amplitude is adjusted by a cylindrical eccentric shaft exciter and an eccentric block. The vibrator is installed on the side plate of the screen box and is driven to rotate by the motor through a V-belt to generate centrifugal inertia force, forcing the screen box to vibrate. The side plate of the screen machine is made of high-quality steel plates, and the side plate is connected to the crossbeam and the base of the exciter with high-strength bolts or ring groove rivets. The vibrator is installed on the side plate of the screen box and is driven to rotate by the motor through a coupling to generate centrifugal inertia force, forcing the screen to vibrate.

The vibrating screen should be started when there is no material on the screen surface, and it is best to avoid starting the machine with material. The screen machine can only be fed after it runs smoothly. Feeding should be stopped before stopping, and the machine should be stopped after the surface material is removed. The operation of the screen machine should be observed frequently during work. If abnormal movement or abnormal sound is found, the machine should be stopped and checked in time to find out the cause and eliminate the fault.

Product Parameter

| Model | sifter |

Feed size (mm) |

Processing capacity | Electric motor | |||

| number of plies |

area (m²) |

Sieve aperture (mm) |

(t/h) | Model |

(kw) Power |

||

| YA1236 | 1 | 4.3 | 6-50 | ≤200 | 80-240 | Y160M-4 | 11.0 |

| 2YA1236 | 2 | 6-50 | ≤200 | 80-240 | Y160M-4 | 11.0 | |

| YA1536 | 1 | 5.4 | 6-50 | ≤200 | 80-240 | Y160M-4 | 11 |

| 2YA1536 | 2 | 6-50 | ≤400 | 100-350 | Y160L-4 | 15 | |

| YAH1536 | 1 | 30-150 | ≤400 | 100-350 | Y160M-4 | 11 | |

| 2YAH1536 | 2 | 30-150 | ≤400 | 200-370 | Y160L-4 | 15 | |

| YA1542 | 1 | 6.5 | 6-50 | ≤200 | 110-385 | Y160L-4 | 11 |

| 2YA1542 | 2 | 30-150 | ≤200 | 110-385 | Y160L-4 | 15 | |

| YA1548 | 1 | 7.2 | 6-50 | ≤200 | 120-420 | Y160L-4 | 11 |

| 2YA1548 | 2 | 6-50 | ≤200 | 120-420 | Y160L-4 | 15 | |

| YAH1548 | 1 | 30-150 | ≤400 | 120-420 | Y160L-4 | 15 | |

| 2YAH1548 | 2 | 30-150 | ≤400 | 120-420 | Y160L-4 | 15 | |

| YA1848 | 1 | 7.5 | 6-50 | ≤200 | 150-525 | Y160L-4 | 15 |

| 2YA1848 | 2 | 6-50 | ≤200 | 150-525 | Y160L-4 | 15 | |

| YAH1848 | 1 | 30-150 | ≤50 | 250-1000 | Y180M-4 | 13 | |

| 2YAH1848 | 2 | 30-150 | ≤400 | 250-1000 | Y180L-4 | 15 | |

| YA2148 | 1 | 10 | 6-50 | ≤210 | 180-630 | Y180M-4 | 18.5 |

| 2YA2148 | 2 | 6-50 | ≤210 | 180-630 | Y180L-4 | 22 | |

| YAH2148 | 1 | 13-200 | ≤400 | 270-1200 | Y180M-4 | 18.5 | |

| 2YAH2148 | 2 | 30-150 | ≤400 | 270-1200 | Y180L-4 | 22 | |

| YA2160 | 1 | 12 | 3-80 | ≤200 | 230-800 | Y180M-4 | 18.5 |

| 2YA2160 | 2 | 6-50 | ≤200 | 230-800 | Y180L-4 | 22 | |

| YAH2160 | 1 | 30-150 | ≤400 | 350-1500 | Y200L-4 | 30 | |

| 2YAH2160 | 2 | 30-150 | ≤400 | 350-400 | Y200L-4 | 30 | |

| YA2448 | 1 | 11 | 6-50 | ≤200 | 200-700 | Y180M-4 | 18.5 |

| YAH2448 | 1 | 6-50 | ≤400 | 310-1300 | Y200L-4 | 30 | |

| 2YAH2448 | 2 | 30-150 | ≤400 | 310-1300 | Y200L-4 | 30 | |

| YA2460 | 1 | 14 | 6-50 | ≤200 | 260-780 | Y200L-4 | 30 |

| 2YA2460 | 2 | 6-50 | ≤200 | 260-780 | Y200L-4 | 30 | |

| YAH2460 | 1 | 30-150 | ≤400 | 400-1700 | Y200L-4 | 30 | |

| 2YAH2460 | 2 | 30-150 | ≤400 | 400-1700 | Y200L-4 | 30 | |

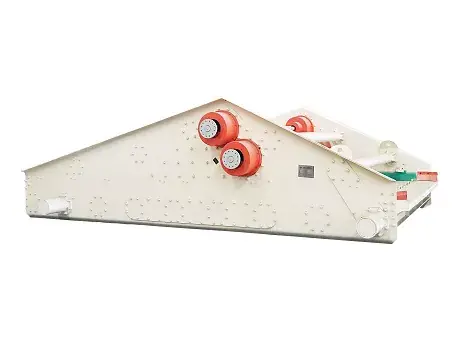

YKR Series Circular Vibrating Screen

YKR series circular vibrating screen is a new type of vibrating screen with circular vibration, multiple layers and high efficiency. The circular vibrating screen adopts a simplified eccentric shaft exciter and an eccentric block to adjust the amplitude. The material screen has a long flow line and multiple screening specifications. It has the characteristics of reliable structure, strong excitation force, high screening efficiency, low vibration noise, durability, convenient maintenance, and safe use. This vibrating screen is widely used in various screening conditions such as stone, metallurgy, metal mining, and coal. The general feed particle size of the YKH-H series is <300mm, and the classification particle size is 2~150mm. The general feed particle size of the YKR-SK series is ≤250mm, and the classification particle size is 2~76mm. The screen can be selected from metal woven screen, rubber screen or polyurethane screen, etc.

Structural features:

1. This series of vibrating screens are divided into single-layer and double-layer structures;

2. The frequency, amplitude and screen surface inclination of the vibrating screen can be adjusted;

3. The vibrating screen adopts a block eccentric external vibrator structure;

4. During the serialization process, the vibrating screen fully considered the specific conditions of my country and the requirements for the generalization, standardization and serialization of various components of the vibrating screen, and adopted a series of advanced technologies

Product Parameter

| Model |

Screen surface width (mm) |

Length of screen surface (mm) |

Inclination (°) |

Vibration times (min-) |

Double amplitude (mm) |

Power (mm) |

Weight (kg) |

| YKR1437H | 1400 | 3750 | 18(15-25) | 800~900 | 7.0-10.0 | 11 | 3832 |

| YKR1645H | 1600 | 4500 | 18(15-25) | 800~900 | 7.0-10.0 | 15 | 5345 |

| YKR1852H | 1800 | 5250 | 18(15-25) | 800~900 | 7.0-10.0 | 18.5 | 6536 |

| YKR2052H | 2000 | 5250 | 18(15-25) | 800~900 | 7.0-10.0 | 22 | 7567 |

| YKR2460H | 2400 | 6000 | 18(15-25) | 800~900 | 7.0-10.0 | 30 | 10904 |

| YKR3060H | 3000 | 6000 | 20(15-25) | 800~900 | 6.0-9.0 | 30 | 13604 |

| YKR3075H | 3000 | 7200 | 20(15-25) | 800~900 | 6.0-9.0 | 45 | 14622 |

| 2YKR3675H | 3600 | 7200 | 20(15-25) | 800~900 | 6.0-9.0 | 2×30 | 24730 |

| 2YKR1437H | 1400 | 3750 | 18(15-25) | 800~900 | 7.0-10.0 | 15 | 6076 |

| 2YKR1645H | 1600 | 4500 | 18(15-25) | 800~900 | 7.0-10.0 | 22 | 8226 |

| 2YKR1852H | 1800 | 5250 | 18(15-25) | 800~900 | 7.0-10.0 | 30 | 10990 |

| 2YKR2060H | 2000 | 6000 | 18(15-25) | 800~900 | 7.0-10.0 | 30 | 12572 |

| 2YKR2460H | 2400 | 6000 | 18(15-25) | 800~900 | 7.0-10.0 | 45 | 14740 |

| 2YKR3060H | 3000 | 6000 | 20(15-25) | 800~900 | 6.0-9.0 | 45 | 18293 |

| 2YKR3075H | 3000 | 7200 | 20(15-25) | 800~900 | 6.0-9.0 | 2×37 | 24230 |

| 2YKR3675H | 3600 | 7200 | 20(15-25) | 800~900 | 6.0-9.0 | 2×45 | 32960 |

| 2YKR2460SK | 2400 | 6000 | 18(15-25) | 800~900 | 7.0-10.0 | 37 | 11785 |

| 2YKR3060SK | 3000 | 6000 | 20(15-25) | 800~900 | 6.0-9.0 | 45 | 14500 |

| 2YKR3075SK | 3000 | 7200 | 20(15-25) | 800~900 | 6.0-9.0 | 2×37 | 19685 |

| 2YKR3675SK | 3600 | 7200 | 20(15-25) | 800~900 | 6.0-9.0 | 2×45 | 30560 |

| 3YKR1852H | 1800 | 5250 | 18(15-25) | 800~900 | 7.0-10.0 | 30 | 11528 |

| 3YKR2060H | 2000 | 6000 | 18(15-25) | 800~900 | 7.0-10.0 | 37 | 13734 |

| 3YKR2460H | 2400 | 6000 | 18(15-25) | 800~900 | 6.0-9.0 | 45 | 16526 |

| 3YKR3060H | 3000 | 6000 | 20(15-25) | 800~900 | 6.0-9.0 | 45 | 17636 |

| 3YKR3075H | 3000 | 7200 | 20(15-25) | 800~900 | 6.0-9.0 | 2×37 | 25210 |

| 3YKR3675H | 3600 | 7200 | 20(15-25) | 800~900 | 6.0-9.0 | 2×45 | 32820 |