English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

What is the difference between a rotary vibrating screen and a linear vibrating screen?

2025-05-06

As a common screening equipment in industrial production, vibrating screens have significant differences in types and application scenarios. Although rotary vibrating screens and linear vibrating screens belong to the same category of vibrating screens, their working principles and structural characteristics are significantly different.

Rotary vibrating screens usually use vertical motors as excitation sources. The design of eccentric blocks makes the screen surface produce three-dimensional composite vibrations. The material presents a spiral diffusion motion trajectory on the screen. This multi-directional motion characteristic enables it to more efficiently handle materials with high viscosity or irregular shapes, such as fine screening in powder metallurgy or food industries.

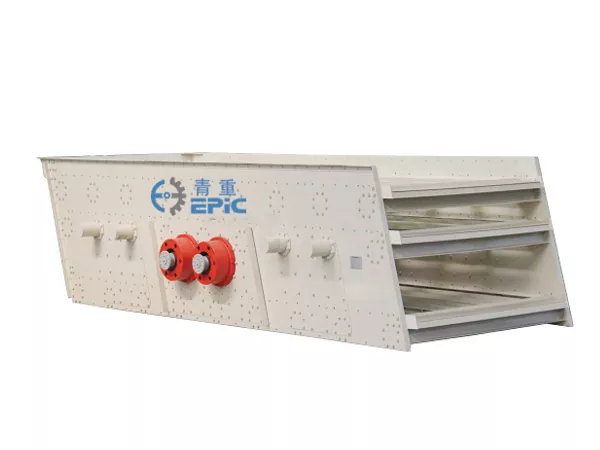

Linear vibrating screens rely on two symmetrically arranged vibration motors to rotate synchronously in opposite directions to form a linear reciprocating vibration along the length of the screen body. The material jumps forward in a parabolic curve on the screen surface. This motion mode is particularly suitable for the rapid classification and processing of bulk materials such as coal and ore. Because of its simple structure and large processing capacity, it is particularly widely used in the mining field.

From the perspective of screening accuracy, the rotary vibrating screen has a better screening effect on fine particles due to its longer material residence time and complex motion trajectory; while the linear vibrating screen is better at efficient sorting of coarse particles due to its fast screening ability brought by high-frequency vibration. In addition, there are differences in the maintenance costs of vibrating screens. Rotary vibrating screens usually require more detailed maintenance due to their complex structure, while linear vibrating screens are highly favored in the heavy industry for their durability and low failure rate. The selection of the two types of vibrating screens needs to be combined with material characteristics, production requirements and process requirements to achieve the best screening effect.