English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

How Do Froth Flotation Cells Support Consistent Mineral Separation in Industrial Operations?

2025-12-16

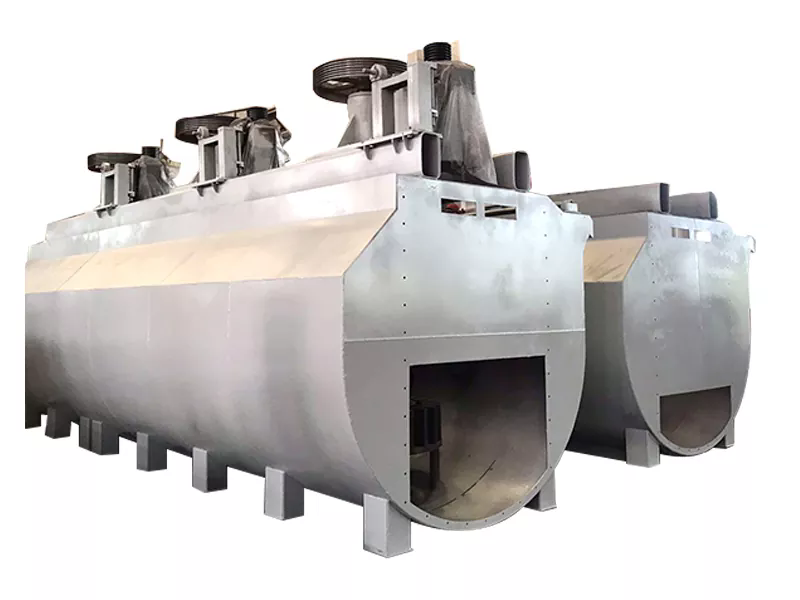

Froth Flotation Cells are a core unit operation in mineral processing, widely applied in the beneficiation of sulfide ores, non-metallic minerals, and selected industrial materials. By utilizing differences in surface physicochemical properties between valuable minerals and gangue, these systems enable selective separation through aeration, reagent conditioning, and controlled hydrodynamics.

How Are Froth Flotation Cells Designed to Operate Within Mineral Processing Circuits?

Froth Flotation Cells are typically positioned after grinding and classification stages, where mineral particles are conditioned to an appropriate size range for surface interaction. The cell structure integrates mechanical agitation, air dispersion, and slurry circulation to create a stable flotation environment. Internally, an impeller–stator assembly promotes particle suspension while simultaneously dispersing air into fine bubbles. These bubbles selectively attach to hydrophobic mineral particles, transporting them to the froth layer for recovery.

The operational consistency of flotation cells depends heavily on the balance between agitation intensity and air input. Excessive turbulence may destabilize bubble–particle attachment, while insufficient energy can lead to poor suspension and uneven reagent distribution. As a result, modern Froth Flotation Cells are engineered with adjustable drive systems, optimized impeller geometries, and modular stator designs to accommodate variations in ore type and throughput.

From a system perspective, flotation cells may be configured as individual units or arranged in banks to form rougher, scavenger, and cleaner stages. Each stage serves a defined role in the overall separation strategy, emphasizing either recovery or concentrate quality. The scalability of flotation cells allows them to be integrated into small pilot plants as well as large-scale concentrators handling thousands of tons per day.

How Do Key Technical Parameters Influence Froth Flotation Cell Performance?

The effectiveness of Froth Flotation Cells is closely linked to their technical specifications, which must be aligned with the characteristics of the processed material and the desired metallurgical outcomes. While configurations vary by application, several core parameters are commonly evaluated during selection and commissioning.

Typical Technical Parameters of Froth Flotation Cells

| Parameter | Description |

|---|---|

| Cell Volume | Ranges from laboratory-scale units to industrial cells exceeding 100 m³, determining slurry residence time |

| Impeller Speed | Adjustable rotational speed to control slurry suspension and air dispersion |

| Air Flow Rate | Regulated input to manage bubble size distribution and froth stability |

| Slurry Density | Designed operating range to ensure effective particle–bubble interaction |

| Drive Power | Sized to maintain consistent agitation under varying load conditions |

| Construction Materials | Selected based on abrasion resistance and chemical compatibility |

Each parameter interacts with the others, forming a dynamic operating window rather than fixed values. For example, higher slurry density may require increased impeller power to maintain suspension, while changes in air flow can influence froth depth and drainage behavior. Engineers typically fine-tune these parameters during commissioning to achieve stable operation across normal feed variability.

Material selection is another critical aspect. Wear components such as impellers, stators, and liners are often manufactured from high-chrome alloys, rubber, or composite materials to withstand prolonged exposure to abrasive slurries. This design consideration supports extended operating campaigns and predictable maintenance planning.

How Are Froth Flotation Cells Applied Across Different Ore Types and Processing Conditions?

Froth Flotation Cells demonstrate broad applicability across metallic and non-metallic mineral processing sectors. In base metal operations, they are commonly used for copper, lead, zinc, and nickel sulfide ores, where selective reagent schemes enable differential flotation. In precious metal circuits, flotation cells are often employed to concentrate gold-bearing sulfides prior to downstream recovery processes.

Non-metallic applications include phosphate, fluorite, graphite, and potash processing, where flotation supports impurity removal or product upgrading. Each application presents unique challenges related to mineralogy, particle size distribution, and surface chemistry. Consequently, flotation cell configuration and operating strategy must be adapted accordingly.

Operational flexibility is essential in these contexts. Many modern Froth Flotation Cells are designed with adjustable froth launders, variable air control systems, and adaptable reagent addition points. These features allow operators to respond to changes in feed composition without extensive mechanical modification.

Environmental and water management considerations also influence application design. Closed-circuit water systems, reagent optimization, and froth management strategies are increasingly incorporated into flotation cell operation to align with regulatory requirements and site-specific sustainability objectives.

How Can Froth Flotation Cells Be Integrated and Managed for Long-Term Operation?

Successful long-term operation of Froth Flotation Cells relies on proper integration within the overall processing plant and disciplined operational practices. Instrumentation such as level sensors, air flow meters, and drive load monitoring systems supports real-time control and early detection of abnormal conditions. When combined with standardized operating procedures, these tools help maintain stable metallurgical performance.

Maintenance strategies typically focus on wear part inspection, lubrication management, and periodic alignment checks. Because flotation cells operate continuously in abrasive environments, proactive maintenance planning reduces unplanned downtime and supports consistent throughput.

Training and operational knowledge are equally important. Operators must understand the relationship between visual indicators—such as froth color, bubble size, and froth mobility—and underlying process conditions. This practical insight enables timely adjustments that preserve separation efficiency under variable feed conditions.

Common Questions About Froth Flotation Cells

Q: How does particle size affect flotation cell operation?

A: Particle size directly influences collision probability between particles and air bubbles. Oversized particles may detach due to weight, while excessively fine particles may remain entrained in the slurry. Froth Flotation Cells are therefore designed to operate within a defined particle size range, typically achieved through upstream grinding and classification control.

Q: How is air distribution controlled within Froth Flotation Cells?

A: Air distribution is managed through adjustable air valves and impeller–stator configurations that regulate bubble generation. Uniform air dispersion across the cell volume ensures consistent bubble–particle contact and stable froth formation, which is essential for predictable separation outcomes.

In industrial mineral processing, Froth Flotation Cells remain a foundational technology due to their adaptability, scalability, and compatibility with a wide range of ore types. Manufacturers such as EPIC continue to develop flotation cell solutions that align with evolving processing requirements and operational standards across global markets. For organizations seeking detailed technical guidance or application-specific configurations, direct consultation is recommended. Contact us to discuss processing objectives, system integration considerations, and available Froth Flotation Cell options tailored to site-specific needs.