English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

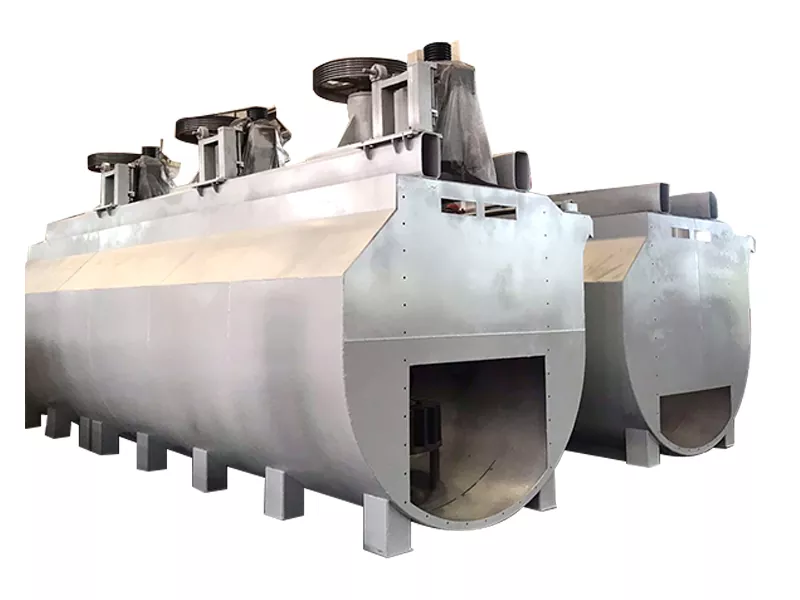

Coarse Granule Froth Flotation Cell

EPIC is a professional Coarse Granule Froth Flotation Cell manufacturer and supplier in China, you can rest assured to buy Coarse Granule Froth Flotation Cell from our factory and we will offer you the best after-sale service and timely delivery.

Send Inquiry

Product Description

The impeller of Coarse Granule Froth Flotation Cell adopts the backward titing blade impeller,and the shape of the ower blade is designed to be consistent with the streamline between the impeller blades of the pulp,which has weak stiring force,large pulp circulation and low power consumption.Together with the tank body and lattice plate,it can fully ensure the suspension and air dispersion of coarse minerals.

The CLF aerated agitator provides good hydrodynamic conditions and improves the load capacity of the mineralized bubbles and the particle size of the flotation mill.

Product Parameter

| Model |

Effective volume (m³) |

Tank size(m) (Length x Width x Height) |

power (kW) |

Producion capacity (m³/min) |

Blower pressure (kPa) |

Air consumption per tank (m/min) |

Feed size (mm) |

Single slot weight (kg) |

|

| CLF-2 | Suction trough | 2 | 1.2×1.6×1.25 | 7.5 | 0.5~2 | ≥14.7 | 0~3 | <1.0 | 1591 |

| Direct current trough | 2 | 1.2×1.6×1.25 | 5.5 | 0.5~2 | ≥14.7 | 0~5 | <1.0 | 1418 | |

| CLF-4 | Suction trough | 4 | 1.6×2.1×1.5 | 15 | 1~4 | ≥19.6 | 0~5 | <1.0 | 3002 |

| Direct current trough | 4 | 1.6×2.1×1.5 | 11 | 1~4 | ≥19.6 | 0~7 | <1.0 | 2702 | |

| CLF-8 | Suction trough | 8 | 1.9×2.5×1.95 | 22 | 1~6 | ≥23.5 | 0~8 | <1.0 | 5168 |

| Direct current trough | 8 | 1.9×2.5×1.95 | 15 | 1~6 | ≥23.5 | 0~12 | <1.0 | 4654 | |

| CLF-16 | Suction trough | 16 | 2.5×3.2×2.4 | 45 | 1~8 | ≥35 | 0~14 | <1.0 | 9230 |

| Direct current trough | 16 | 2.5×3.2×2.4 | 37 | 1~8 | ≥35 | 0~16 | <1.0 | 8970 | |

Hot Tags: Coarse Granule Froth Flotation Cell

Related Categories

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Related Products

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy