English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

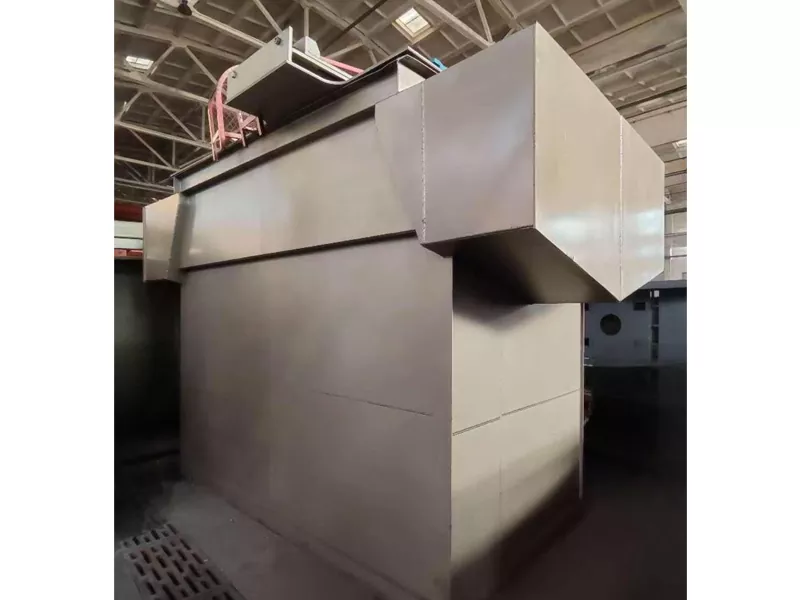

Vertical Stirred Mill

Send Inquiry

Vertical stirred mill is a kind of grinding equipment used in mining, metallurgy, chemical industry and other industries, mainly used for fine grinding and ultrafine grinding. It grinds the material to micron or even nanometer level through friction, impact and shear between the stirring medium and the material. Vertical stirred mill is widely used in fine processing of non-metallic minerals, metal minerals, chemical raw materials and other materials.

Advantages and characteristics

1. High efficiency and energy saving: Compared with traditional ball mills, vertical stirred mills have lower energy consumption and higher grinding efficiency.

2. Controllable fineness: By adjusting the stirring speed, medium size and grinding time, the fineness of the product can be accurately controlled.

3. Compact structure: The vertical design occupies a small area and is suitable for sites with limited space.

4. Easy operation: High degree of automation, easy operation and maintenance.

5. Low noise and low pollution: Low noise and less dust pollution during operation, in line with environmental protection requirements.

6. Strong adaptability: Suitable for grinding a variety of materials, including materials with higher hardness.

Working Principle

The working principle of the vertical stirred mill mainly includes the following steps:

1. Feeding: The material enters the grinding chamber through the feed port.

2. Stirring and grinding: The agitator drives the grinding medium (such as steel balls, ceramic balls, etc.) to rotate at high speed, generating strong friction, impact and shear force to crush the material.

3. Classification: The ground material passes through the classification device, and the material that meets the fineness requirements is discharged, and the material that does not meet the requirements continues to be ground.

4. Discharging: The material that meets the fineness requirements is discharged through the discharge port to complete the entire grinding process.

The vertical stirred mill occupies an important position in mining equipment with its advantages of high efficiency and energy saving, controllable fineness, and simple operation. Its working principle is to achieve fine grinding of materials through the interaction between the stirring medium and the material, and is widely used in many industries.

Product Parameter

| Device Model | LSM-800 | LSM-1000 | LSM1000 | LSM-1200 |

| Model (mm) | 800/950 | 990/1140 | / | 1200/1350 |

| Cylinder height(mm) | 990/670 | 990/670 | 1300/630 | 990/670 |

| Effective volume(m³) | 0.65 | 1 | 3.4 | 1.5 |

| Processing capacity (t/h) | 按工艺 | 按工艺 | 按工艺 | 按工艺 |

| Power(kW) | 22 | 37 | 37×2 | 45 |

| Spindle speed(r/min) | 222 | 205 | 231/255 | 175 |