English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Honest and trustworthy manufacturing of first-class mineral processing equipment in China

2025-06-07

The mineral processing equipment produced by Qingzhong Machinery, including crushers, ball mills, classifiers, flotation machines, etc., has received high praise from domestic and foreign users. Qingzhong's sales philosophy is to manufacture first-class mineral processing equipment in China with integrity and trustworthiness, so that old users can retain new users and promote them. One word from users is worth ten thousand words from us. Over the years, we have not only retained old users, but also made new users who choose Qingzhong become repeat customers of Qingzhong. The quality of Qingzhong's mineral processing equipment is obvious to all. The processing equipment of Qingzhong ball mill and other mineral processing equipment is our core advantage, including large annealing furnaces, large horizontal lathes from Qiqihar First Machine Tool Factory, large CNC 8-meter vertical lathes from Qiyi Machine Tool, and large gear hobbing machines from Russia.

For many years, Qingzhong ball mills have been favored by customers, not only for their good product quality but also for their beautiful appearance. Our mills achieve both internal and external beauty. We strive for excellence in every process of the grinder. After the end cover of the ball mill is cast, it needs to undergo infrared inspection to ensure that the casting density and defects are problem free before cleaning and sandblasting. After passing through the annealing furnace, the outer layer of the cylinder will have an oxide layer like soybean skin. The exposed area will be sprayed with steel balls, followed by two layers of primer, and then sprayed with external paint after 24 hours. The color of the paint on the surface of the green heavy mill is something that many peers cannot learn. Our company specially commissioned Qingdao Paint Factory to process the gold powder paint, which is both beautiful and will not peel off. The ball mill transported to the beneficiation plant is beautiful and elegant.

1. Large annealing furnace

Our factory's large annealing furnace has a width and height of 5.5 meters and a length of 13 meters. It is one of the largest annealing furnaces in the Qingdao area. This furnace is used for annealing riveting and welding parts, eliminating the hardness in the steel plate and effectively stabilizing the welded parts without deformation or cracking. Annealing is an essential special process for the barrel of a ball mill. The quality of a ball mill without annealing is poor because prolonged operation can cause equipment instability and lack of center, as well as continuous fatigue operation of the barrel. If the barrel cracks, it cannot be welded, ultimately leading to the paralysis and shutdown of the mill.

2. Large specialized ball mill cylinder processing lathe

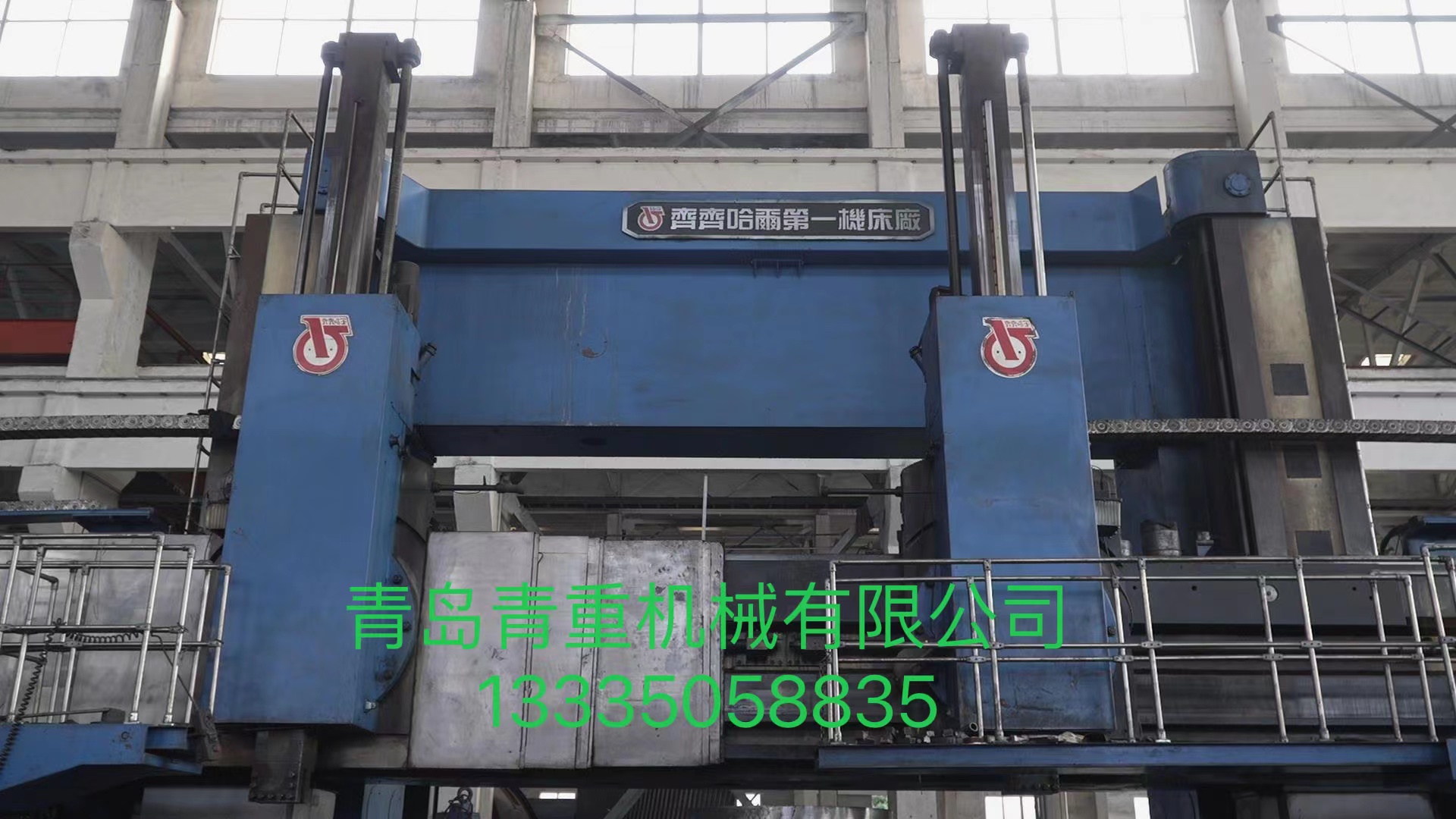

This machine tool is a large horizontal lathe specially processed by Qiqihar First Machine Tool Factory, a renowned Chinese machine tool manufacturer commissioned by Qingzhong. Its advantages include that the flange machine tool for processing can be moved for cutting, as the lathe cannot move after aligning the cylinder, ensuring that one cut is completed to ensure the concentricity of the ball mill cylinder, which is an important factor in casting a good ball mill.

3. Large CNC 8-meter vertical lathe

This machine tool is also produced by Qiyi Machine Tool Factory, a well-known Chinese machine tool enterprise. Qingzhong's philosophy is that good ore dressing equipment must have good processing equipment. If the precision of the processing equipment cannot be achieved, how can a good ball mill be processed. The price of the large CNC 8-meter vertical lathe from Qiyi Machine Tool Factory is 6.8 million yuan, while the price of the same specification equipment from Qingdao Machinery Factory is half of the price of 3.6 million yuan. However, Chairman Li Mingrui immediately set a higher price for Qiyi brand machine tools. Good processing equipment is an important factor in producing good ball mills.

4. Large gear hobbing machines in Russia

Russia's large gear hobbing machines are also processors of ball mill gears. The transmission used is a double worm gear transmission, while the gear transmission produced by our domestic Wuhan Heavy Machinery Factory is also a gear transmission. The precision of the processed gears is far lower than that of the worm gear transmission. Large gears are the most important part of ball mills, and high precision equipment can operate smoothly without noise and greatly increase the service life. Only when the equipment is stable can there be no quality problems. Therefore, we, Qingzhong, would rather spend 18 million yuan to buy imported gear hobbing machines than buy the 8 million yuan Wuhan Heavy Machinery from China. The evaluation of new and old users shows that Qingzhong mills have good quality and operate smoothly without problems. It is really a BMW Mercedes Benz car in ball mills. This is in line with the function of this gear hobbing machine. It's inseparable.

5. This machine is processing the helical teeth of the 3660 grinder's large gear, and our rolling gear can process the diameter of the helical teeth.

6. Casting the discharge end cover of ball mill No.35

Qingdao Foundry has the highest quality in the country, with first-class density and material. Many castings from Southeast Asia, South Korea, and Japan come to Qingdao for procurement. After the castings are processed, there are no air holes or sand holes, whether it is magnetic particle inspection or visual observation. The quality can be called first-class. As the saying goes, good materials, good craftsmanship, and good drawings are the key to good equipment.

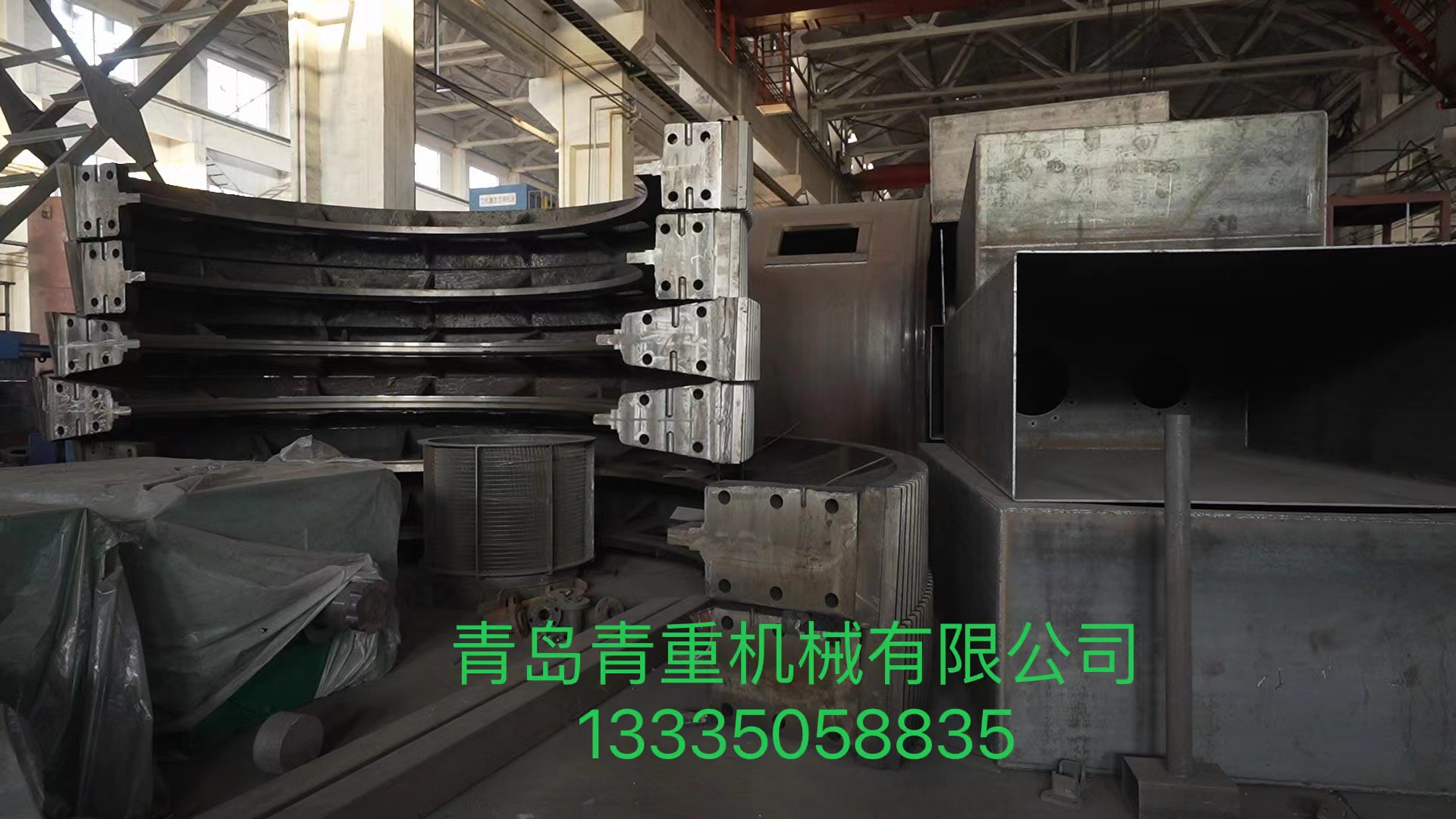

7. This is a 3.2-meter, 3.6-meter, and 2-meter series large gear. Qingzhong has strong financial strength and a semi-finished product inventory of over 20 million in various specifications to prevent customers from rushing and ensure the supply of products to customers in a short period of time.

8. A movable large rocker arm drill with an arm length of 1 meter

This equipment is specifically designed for drilling and punching the mill cylinder, end cover, and large gear to ensure the concentricity of the cylinder. This picture shows the drilling and punching of the 3660 ball mill end cover and cylinder body ordered by Guizhou Jinzhengda Chemical Co., Ltd.

9. A first-class large-scale boring and milling machine in China

This machine tool is produced by Kunming Machine Tool Factory of Shenyang Machinery Industry Group, with a value of 7.2 million yuan and fully CNC computer-controlled. Among the same industry and products in China, Kunming floor boring and milling machines are of excellent quality, ranking first. The precision of the parts processed by this machine tool meets the requirements of the drawings, and even exceeds them. As the saying goes, good processing equipment is necessary to ensure the production of good products. This is the production philosophy that Qingzhong has always believed in.