English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

How to use the vibrating screen reasonably to improve the efficiency of the mineral processing production line?

2025-02-18

In actual production operations, the vibrating screen always fails to reach the set processing capacity. What should I do if the efficiency is low? As an important equipment in the screening industry, the screening effect of the vibrating screen is not only crucial to the product quality, but also has a direct impact on the efficiency of the next operation. The following are some measures and techniques to improve the efficiency and performance of the vibrating screen.

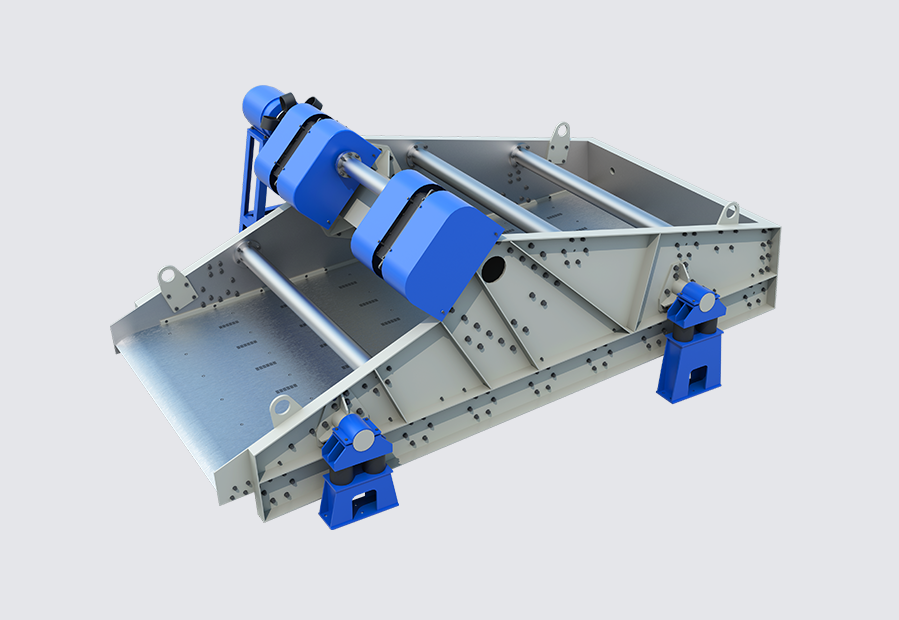

01 Choose the right type of vibrating screen

Although the screening effect mainly depends on the properties of the screened material, different types of screening equipment can be used to obtain different screening effects for the same material. For example:

The screening efficiency of the fixed screen is low;

The screening efficiency of the moving screen is related to the movement form of the screen surface. The particles are shaken on the screen surface close to the direction perpendicular to the screen hole. The higher the vibration frequency, the better the screening effect;

On the screen surface of the shaking screen, the particles mainly slide along the screen surface. Since the shaking frequency of the shaking screen is lower than that of the vibrating screen, the screening effect of the shaking screen is poor;

The screening efficiency of the cylindrical screen is low because the screen surface is easy to be blocked.

In addition, different types of vibrating screens should be selected for different purposes, such as:

Circular vibrating screens are generally used for pre-screening and inspection screening of materials;

Probability screens, equal thickness screens and large vibrating screens are used for grading crushed materials;

Linear vibrating screens are used for dehydration and de-mediuming of materials;

Probability equal thickness screens are better for sand removal and mud removal of materials.

In actual production, it is also necessary to select non-metallic screens with larger sieve hole sizes, larger effective screening areas, and higher sieve opening rates as much as possible according to specific conditions, while meeting the product particle size requirements, and select appropriate sieve hole shapes to improve the screening ability and work efficiency of material particles.

02 Reasonable selection of vibration motors and adjustment of exciting force

The reasonable selection of vibration motors is one of the key links affecting the performance of vibrating screens, and the size of exciting force is the core factor affecting the productivity of vibrating screens.

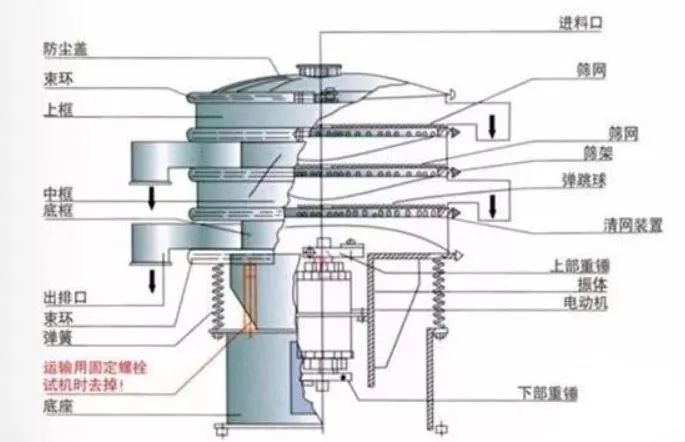

(1) Selection of vibration motor

As the vibration source of the vibrating screen, the vibration motor should have the advantages of reasonable design, simple structure, compactness, high excitation efficiency, energy saving, and easy installation and debugging. The selection of the vibration motor includes parameters such as working frequency, maximum excitation force, and power. First, the working frequency and excitation force should be selected. The speed of the vibration motor should be close to the working frequency; the maximum excitation force must be within the range of the selected motor's synthetic excitation force, and then the power of the vibration motor should be selected according to the working frequency and maximum excitation force.

(2) Adjustment of excitation force

The productivity of the vibrating screen is exponentially related to the excitation force. The increase in excitation force causes a rapid increase in productivity, while the blockage rate decreases rapidly with the increase in excitation force. The excitation force also has a certain influence on the pass rate and crushing rate of the screen. The change law is wave-shaped: when the excitation force is too small, the pass rate and crushing rate are poor; when the excitation force is too large, the friction of the eccentric blocks at both ends of the vibration motor shaft will increase. Under high-speed rotation, it is easy to damage the motor and reduce the service life of the motor. Therefore, it is very important to reasonably adjust the size of the excitation force. The exciting force of the vibration motor is the centrifugal inertia force generated by the high-speed rotating eccentric block. By changing the eccentricity and thus the amplitude of the exciting force, the exciting force can be adjusted.

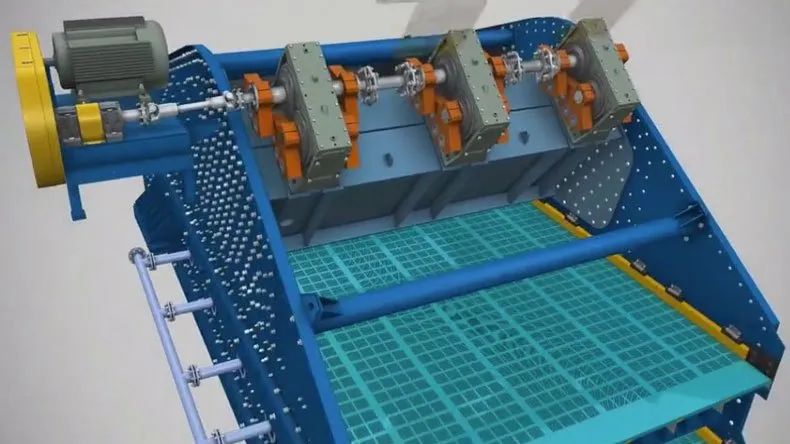

03 Improve the movement mode of the screen surface

The movement mode of the screen surface has a great influence on the working efficiency of the vibrating screen. The ideal movement mode of the screen surface should be:

1) The vertical amplitude of the screen surface feeding end should be greater than the vertical amplitude of the discharge end.

This is because the larger vertical amplitude at the feeding end can effectively stratify the thicker material at this end. At the same time, with the help of the inclination angle, the excess material at this end can be quickly spread to the middle of the screen surface, so that the fine-grained material can be stratified in a relatively thin material layer, increasing the actual use area of the screen surface. When the material reaches the discharge end, the material has been stratified. At this time, only a smaller vertical amplitude is needed to ensure that the fine-grained material has good screening conditions. Too large vertical amplitude will disrupt the screening environment of the fine-grained material.

2) Along the length of the screen surface, starting from the feeding end, the material movement speed should be in a decreasing state.

This is because the material movement speed decreases, but the material layer maintains a certain thickness on the entire screen surface, so that the fine-grained material is screened in layers on a relatively longer range of the screen surface, increasing the actual use area of the screen. At the same time, the amount of screen penetration along the length of the screen tends to be uniform, giving full play to the screen penetration potential of the screen surface. The equal-thickness screen and dual-frequency vibrating screen developed in recent years have overcome the shortcomings of the ordinary vibrating screen with a constant amplitude of the entire screen surface and low unit screening capacity, so that the feed end has a larger amplitude and the discharge end has the same amplitude as the ordinary vibrating screen, thereby improving work efficiency.

04 Use non-metallic screens

Non-metallic screens have the following advantages:

1) Improve screening efficiency. It can improve the screening efficiency of metal screens by about 20%.

2) Good wear resistance and long service life. Its average life is more than 25 times that of metal screens.

3) Reduce installation time and improve equipment operation rate. Since the service life of non-metallic screens is greatly extended, the number of screen surface replacements is reduced, and the equipment operation rate is generally 15% higher than that of metal screens.

4) Reduce noise and improve the working environment.

In addition to resonating with the screen box, the metal screen also produces some vibrations during operation. This phenomenon is more obvious after wear. In addition, the rigid collision of the material on the box surface and the vibration of other parts generate higher noise. The entire screen plate of the non-metallic material screen is a whole, which has a certain buffering effect and can reduce the noise by about 20dB (A).

05 Use multi-channel feeding method

The vibrating screen generally uses one-way feeding. After the material is supplied to the screen surface, most of the materials smaller than the separation particle size quickly pass through the screen holes at the feeding end and become the under-screen product. The 1/3~1/2 screen surface from the discharge end, in addition to continuing to play a certain screening role, mainly plays a transportation role, so the utilization rate of the screen surface is not high. If multi-channel feeding is used, it is equivalent to increasing the width of the screen surface and reducing the thickness of the material layer supplied to the screen surface, which is conducive to the fine-grained material quickly contacting the screen surface through the screen holes. At the same time, the screen surface is fully utilized, reducing the unnecessary transportation distance of coarse particles, thereby improving the screening work efficiency.

06 Strengthen operation management

Operation and maintenance also have a certain impact on the performance of the vibrating screen. In order to make the vibrating screen run efficiently, it must be carefully operated in strict accordance with the operating procedures, such as feeding evenly, continuously and in moderation, ensuring that the material is evenly distributed along the entire width of the screen surface, so as to facilitate the screening of fine particles and obtain higher processing capacity and screening efficiency.

In addition, it is also necessary to strengthen the maintenance and care of the screen machine, such as timely cleaning of the screen surface and repairing and replacing damaged screen surfaces to ensure the good condition of the equipment, which is of great significance to ensure the stable and high production of the screening process engineering.