English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

How Does Cyaniding Equipment Improve Gold Recovery and Site Safety?

If you’ve ever felt like cyanidation is “effective, but stressful,” you’re not imagining it. The chemistry works—yet the day-to-day reality can be messy: variable ore, reagent overspending, carbon losses, unexpected downtime, and the constant pressure to operate safely and consistently. This article breaks down what Cyaniding Equipment should actually do for you, what to ask before you buy, and how to avoid the most expensive mistakes.

Abstract

Modern Cyaniding Equipment is not just a set of tanks—it’s a connected system designed to control leaching conditions, stabilize recovery, reduce reagent waste, and keep cyanide handling predictable. Buyers typically struggle with four pain points: inconsistent recovery, high operating cost, weak safety controls, and maintenance headaches. Below, you’ll get a practical, plant-floor view of cyaniding modules (leaching, adsorption, desorption/electrowinning, detox, and instrumentation), a selection matrix, commissioning tips, and an FAQ section you can use during supplier conversations.

Table of Contents

- The real buyer pain points

- What “Cyaniding Equipment” includes

- A clear process map from ore to doré

- Key modules and what to check

- Sizing and specification basics

- Safety and cyanide control that actually holds up

- Where operating costs really come from

- Reliability and maintenance design

- Supplier questions you should ask

- FAQ

- Wrap-up

Outline at a Glance

- Translate “I need cyanidation” into a complete, controllable equipment scope.

- Identify which module is driving your losses (recovery, reagent, carbon, or downtime).

- Use a simple matrix to compare solutions for your ore type and constraints.

- Walk into supplier meetings with a checklist that exposes weak designs fast.

The Real Buyer Pain Points

When people shop for Cyaniding Equipment, they often say “I need higher recovery.” What they usually mean is: “I need recovery that stays high even when the ore changes, the operators rotate, and the site is remote.” Here are the pain points that show up again and again:

- Recovery swings caused by ore variability, grind issues, oxygen limitations, or poor pH control.

- Reagent cost creep from overdosing cyanide or lime “just to be safe.”

- Carbon problems such as fouling, attrition loss, or poor adsorption kinetics.

- Downtime from pump/valve failures, abrasive slurry wear, or hard-to-access layouts.

- Safety stress around cyanide storage, dosing, and emergency response readiness.

Good equipment design doesn’t remove all complexity, but it should remove the guesswork.

What “Cyaniding Equipment” Includes

At minimum, Cyaniding Equipment should be understood as a system that supports these functions:

- Leaching: provide time, mixing, and chemistry control for dissolution.

- Gold capture: adsorption onto activated carbon (CIP/CIL) or precipitation routes.

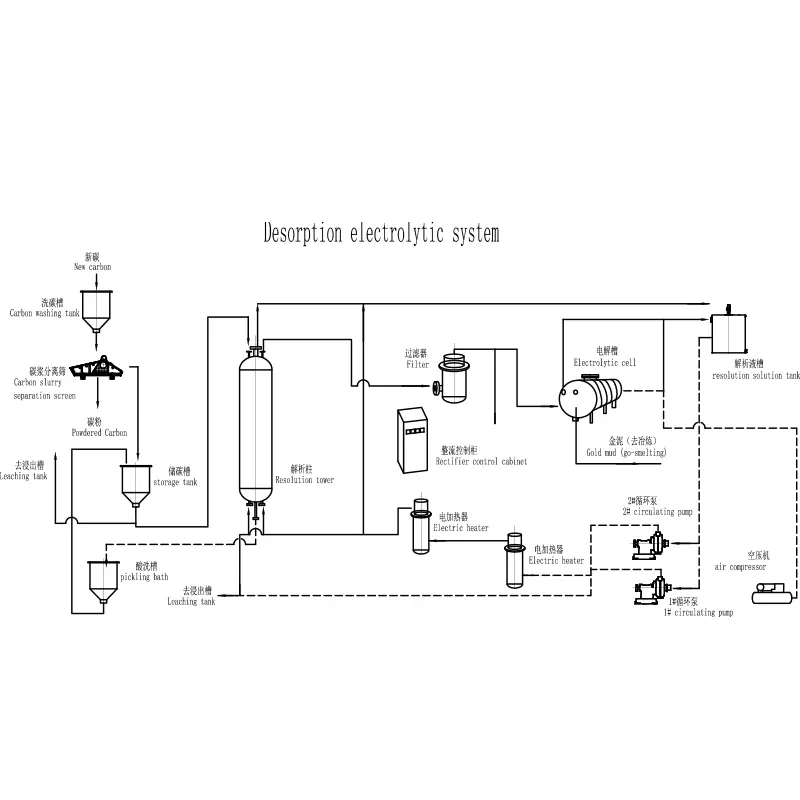

- Gold recovery: desorption and electrowinning (or alternative recovery circuits).

- Detox and tailings handling: reduce residual cyanide to acceptable levels.

- Instrumentation and control: measure and stabilize pH, dissolved oxygen, flow, and dosing.

If a supplier only talks about “tanks,” push them to define the entire flow and the control points. Cyanidation is forgiving in lab conditions; it is not forgiving in chaotic field conditions.

A Clear Process Map from Ore to Doré

While every plant differs, most cyanidation routes follow a recognizable backbone. Use this map to sanity-check whether a proposed package is complete:

| Stage | What It Must Achieve | Typical “Hidden” Risk |

|---|---|---|

| Pre-treatment (as needed) | Make gold accessible and prevent cyanide consumption spikes | Ignoring preg-robbing, high copper, or reactive sulfides |

| Leaching | Stable mixing, controlled pH, and sufficient oxygen | Dead zones, poor oxygen transfer, erratic pH from weak lime system |

| Adsorption (CIL/CIP) | Capture dissolved gold efficiently | Wrong carbon size/transfer method; carbon losses |

| Elution / Desorption | Strip gold from carbon reliably | Inconsistent heating/flow leads to low stripping efficiency |

| Electrowinning / Smelting | Recover and produce doré | Undersized cells, poor electrolyte management, sludge handling issues |

| Detox | Reduce residual cyanide before discharge/tailings | Design doesn’t match throughput variability or tailings chemistry |

Key Modules and What to Check

1) Leaching tanks and agitation

- Is the mixing design suited for your slurry density and abrasiveness?

- Can the system maintain stable pH under ore variability?

- Is oxygen addition practical on your site (and is oxygen transfer considered in the design)?

- Does the layout allow easy inspection of impellers, liners, and bearings?

2) Carbon adsorption and transfer

- Are interstage screens robust enough to prevent carbon carryover?

- Is carbon transfer engineered to reduce breakage and loss?

- Is the design friendly to cleaning and carbon inventory control?

3) Desorption and electrowinning

- Does the elution circuit match your carbon loading expectations?

- Are heating and flow controls stable (not “operator-dependent”)?

- Is sludge handling planned, not improvised?

4) Cyanide dosing and measurement

- Is dosing automated with interlocks, or purely manual?

- What is the plan for calibration and sensor maintenance in a real mine environment?

- Are sampling points safe and well-positioned, or an afterthought?

5) Detox

- Is the detox design based on your discharge targets and tailings chemistry?

- Can it handle short-term spikes without forcing a shutdown?

Practical hint: A proposal that looks cheaper on paper often pushes cost into operations—extra cyanide, extra lime, extra maintenance labor, and more “heroic” operator behavior. The bill arrives later.

Sizing and Specification Basics

You don’t need to be a metallurgist to ask sizing questions that protect your budget. For Cyaniding Equipment, the core sizing logic revolves around throughput, residence time, and mass transfer. Before accepting any final design, make sure these inputs are explicitly stated:

- Design throughput (average and peak, plus expected seasonal variability).

- Target grind size and what happens if the mill drifts coarser.

- Leach residence time and whether it is based on tests or assumptions.

- pH and alkalinity plan (including lime preparation and dosing stability).

- Oxygen strategy (air, oxygen, or none) and the expected impact on kinetics.

- Carbon inventory (how much carbon, where it sits, and how it’s monitored).

If a supplier cannot explain these in plain language, treat it as a risk signal—not a technicality.

Safety and Cyanide Control That Actually Holds Up

Safety isn’t a poster on the wall. With cyanidation, it’s built into physical design and routine control. Strong Cyaniding Equipment packages typically include:

- Contained storage and transfer with clear spill paths and bunding logic.

- Interlocked dosing so cyanide can’t be added when key conditions aren’t met.

- Clear sampling design that reduces exposure risk during routine checks.

- Emergency readiness as part of the operating procedure set, not an add-on document.

From a buyer’s perspective, your job is simple: force the proposal to show exactly how people interact with the system. Where do they stand? What do they touch? How do they isolate equipment? How do they respond to a pump seal failure at 2 a.m.?

Where Operating Costs Really Come From

If your cost per ounce is drifting upward, it’s usually not one dramatic failure—it’s small leaks in the system that compound. In cyanidation, the most common cost drivers are:

- Cyanide consumption driven by reactive minerals, overdosing habits, or poor control loops.

- Lime consumption when pH control is unstable or slurry chemistry is not well understood.

- Carbon loss via attrition, screen issues, or poor transfer design.

- Power and maintenance from over-agitation, under-designed wear parts, and hard-to-service layouts.

| Symptom | Likely Root Cause | Equipment Feature That Helps |

|---|---|---|

| Recovery drops when ore changes | pH/DO instability; poor mixing; insufficient residence time | Robust agitation, better control instrumentation, flexible tank capacity |

| Cyanide spend keeps rising | Overdosing; high cyanide-consuming minerals; poor measurement | Controlled dosing, reliable sampling points, smarter interlocks |

| Carbon inventory “mysteriously” shrinks | Screen failures; transfer losses; attrition | Durable interstage screens, gentle transfer design, clear carbon accounting |

| Frequent shutdowns | Wear parts, pump sealing, access issues | Wear-resistant materials, maintenance access, standardized spares |

Reliability and Maintenance Design

A cyanidation circuit can look “complete” and still be unreliable if maintenance was not designed in. Ask how the supplier approaches:

- Materials selection for abrasive slurry zones and cyanide-contact zones.

- Access to screens, impellers, liners, pumps, and instrumentation.

- Spare parts strategy that matches your site reality (lead times, logistics, stocking).

- Standardization to reduce the number of unique wear items.

In remote operations, “easy to maintain” can be worth more than “slightly more efficient on paper.”

Supplier Questions You Should Ask

Use this checklist in meetings. It’s designed to surface weak proposals quickly—without turning the conversation into a debate.

- Which ore risks are assumed away, and which are actively engineered for?

- What are the design inputs for residence time, pH range, and oxygen strategy?

- How is cyanide dosing controlled, and what happens during sensor failure?

- How is carbon loss prevented and measured in routine operations?

- What is the maintenance access plan for screens, agitators, and pumps?

- What are the recommended operator checks per shift, and how are they made safe?

- What commissioning support is included, and what operator training is provided?

If you’re evaluating vendors, it can help to talk with a manufacturer that can supply a full cyanidation package and support the integration details. For example, Qingdao EPIC Mining Machinery Co.,Ltd. provides mining processing equipment solutions where cyanidation packages are considered as systems—leaching, adsorption, recovery, and control—rather than a disconnected set of tanks.

FAQ

What makes Cyaniding Equipment “modern” rather than basic?

Modern designs focus on controllability and repeatability: stable dosing, reliable measurement, safer sampling, robust wear protection, and layouts that reduce operator improvisation. The goal is consistent recovery with less reagent waste and fewer shutdowns.

Can Cyaniding Equipment handle low-grade ore economically?

It can, but only when the circuit is engineered around your kinetics and consumption profile. Low-grade operations tend to be sensitive to reagent overspending and downtime, so control systems, wear design, and carbon management become especially important.

How do I know if I need CIP or CIL?

The choice usually depends on leach kinetics and how quickly dissolved gold should be captured. If gold dissolves quickly and you want immediate capture, CIL can be attractive. If leaching benefits from separation before adsorption, CIP may fit better. Metallurgical tests and practical site constraints should drive the decision.

Why does cyanide consumption sometimes spike suddenly?

Common causes include ore mineral changes, poor pH control, unexpected oxygen limitation, or contamination in the process water. A good control plan plus reliable sampling points makes these spikes easier to diagnose and correct quickly.

What should I prioritize if my site is remote and short-staffed?

Prioritize maintainability and automation that reduces manual handling: durable screens, accessible equipment layout, standardized spares, interlocked dosing, and clear operating routines that don’t rely on “one expert operator.”

Wrap-up

Buying Cyaniding Equipment is ultimately about reducing uncertainty. The chemistry may be proven, but your profitability depends on consistent control, practical maintenance, and safety that works on real shifts with real people. If you’re planning a new plant or upgrading an existing circuit, bring your ore realities, throughput targets, and site constraints to the table—and insist on a proposal that treats cyanidation as a complete, controllable system.

Ready to turn your cyanidation plan into a reliable, cost-stable operation? Share your ore type, target capacity, and site conditions, and contact us to discuss a practical equipment configuration that fits your plant and your operators.