English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

How Does Iron Removal Equipment Improve Water and Mineral Purification Efficiency?

Iron removal plays a crucial role in ensuring clean water and efficient mineral processing across multiple industries. This article explores the science, design, and benefits of Iron Removal Equipment, explaining how it works, why it matters, and what makes Qingdao EPIC Mining Machinery Co., Ltd. a trusted name in this field. The content will cover product parameters, working principles, and detailed FAQs that address common user concerns. Readers will gain a full understanding of how these systems function and why they are essential for water treatment, mining, and environmental protection.

Contents

-

What Is Iron Removal Equipment and How Does It Work?

-

Why Is Iron Removal Equipment Critical for Water and Mining Applications?

-

What Are the Technical Specifications and Product Advantages?

-

FAQ: Everything You Need to Know About Iron Removal Equipment

-

About Qingdao EPIC Mining Machinery Co., Ltd. & Contact Us

1. What Is Iron Removal Equipment and How Does It Work?

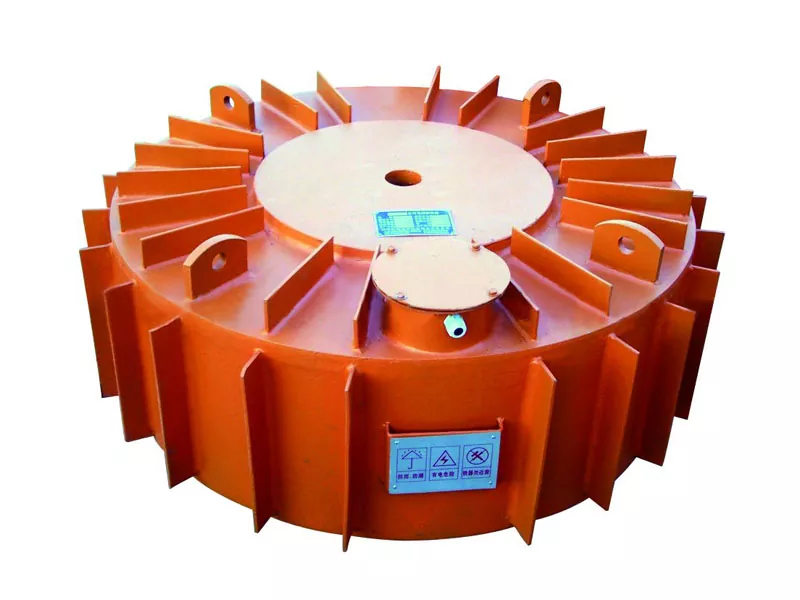

Iron Removal Equipment is designed to extract dissolved or particulate iron from water, minerals, and industrial fluids. This technology is widely applied in water treatment plants, mining operations, and industrial production facilities where iron contamination can cause scaling, discoloration, or reduced product purity.

So, how does it actually work?

The process typically involves oxidation, filtration, and separation stages. Water or slurry containing iron passes through a pre-oxidation system that converts soluble ferrous ions (Fe²⁺) into insoluble ferric ions (Fe³⁺). The resulting ferric hydroxide particles are then filtered through a specialized medium or magnetic separator, effectively removing iron residues and improving overall purity.

Key Process Stages:

-

Oxidation: Converts soluble iron into filterable form.

-

Filtration: Captures ferric particles through sand, resin, or magnetic beds.

-

Backwashing: Cleans and restores the media for long-term use.

-

Monitoring: Sensors track turbidity and iron concentration levels.

Applications:

-

Groundwater purification

-

Mining ore treatment

-

Industrial wastewater recycling

-

Food and beverage production

-

Boiler and cooling system maintenance

This multi-stage treatment process ensures consistent performance, high purity, and system longevity.

2. Why Is Iron Removal Equipment Critical for Water and Mining Applications?

Excessive iron in water or minerals can cause a range of industrial and environmental problems. Rust-colored water, metallic taste, fouled pipes, and damaged processing equipment are just a few consequences of unmanaged iron levels.

In mining, for instance, iron deposits interfere with mineral flotation, reduce product grade, and increase operational costs. In municipal systems, iron buildup leads to corrosion, clogged filters, and bacterial growth.

Why You Need Reliable Iron Removal Equipment:

-

Improves product purity: Ensures minerals, metals, and water meet regulatory standards.

-

Protects infrastructure: Prevents rust, corrosion, and scaling in pipelines and tanks.

-

Reduces maintenance costs: Less downtime, fewer filter replacements.

-

Enhances efficiency: Stabilizes water chemistry and supports continuous processing.

-

Ensures environmental compliance: Meets international water quality guidelines.

Common Problems Solved by Iron Removal Equipment:

| Problem | Effect | Solution by Iron Removal Equipment |

|---|---|---|

| Rust-colored water | Unpleasant taste and appearance | Removes dissolved iron through oxidation and filtration |

| Corrosion in pipelines | Reduces lifespan of metal pipes | Prevents oxidation buildup |

| Mineral contamination | Decreases product quality | Ensures consistent mineral separation |

| Bacterial iron fouling | Promotes biofilm formation | Eliminates source of bacterial growth |

| High maintenance cost | Frequent replacements | Extends filter and equipment life |

Iron Removal Equipment plays a preventative role — solving root issues before they evolve into expensive system failures.

3. What Are the Technical Specifications and Product Advantages?

Every system from Qingdao EPIC Mining Machinery Co., Ltd. is engineered with precision, integrating advanced oxidation technology, automatic control, and durable materials that guarantee stability under harsh industrial environments.

Typical Technical Specifications

| Model | Flow Rate (m³/h) | Working Pressure (MPa) | Power (kW) | Filtration Precision (μm) | Iron Removal Efficiency (%) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| EPIC-IR10 | 10 | 0.6 | 1.5 | 5 | 98% | 800×500×1500 |

| EPIC-IR30 | 30 | 0.8 | 2.2 | 3 | 99% | 1200×800×1800 |

| EPIC-IR50 | 50 | 1.0 | 3.0 | 1 | 99.5% | 1500×1000×2000 |

Key Product Features:

-

Automatic Control: Programmable system for real-time monitoring and backwashing.

-

High Efficiency Media: Multi-layer filters enhance particle capture rate.

-

Modular Design: Easy to install, maintain, and upgrade.

-

Corrosion-Resistant Materials: Ensures long service life under variable pH levels.

-

Energy Saving: Optimized flow channels reduce power consumption.

-

Compact Structure: Space-efficient for both on-site and factory use.

Product Advantages:

-

Stable operation with minimal manual intervention.

-

Customizable design based on client water quality.

-

Low chemical consumption and sustainable performance.

-

Optional integration with smart monitoring or Wi-Fi control systems.

These features make the Iron Removal Equipment from Qingdao EPIC Mining Machinery Co., Ltd. ideal for diverse industrial applications, ensuring consistent water clarity and mineral purity.

4. FAQ: Everything You Need to Know About Iron Removal Equipment

Q1: What is the main function of Iron Removal Equipment?

A1: It removes dissolved and suspended iron from water or slurry using oxidation and filtration, improving purity and preventing corrosion.

Q2: How long does the system last?

A2: With proper maintenance, the equipment typically lasts 10–15 years, depending on operational conditions.

Q3: Can it handle high iron concentrations?

A3: Yes. Systems are designed to treat concentrations from 0.3 mg/L up to 50 mg/L efficiently.

Q4: What maintenance is required?

A4: Routine backwashing and occasional filter media replacement ensure consistent performance.

Q5: Does it remove other metals besides iron?

A5: Yes, many models can also remove manganese, arsenic, and turbidity depending on configuration.

Q6: Is the system environmentally friendly?

A6: Absolutely. It uses low-chemical processes and complies with global environmental standards.

Q7: Can it be used in residential applications?

A7: Smaller models are suitable for domestic water filtration, especially in rural or well-water systems.

Q8: How does it affect taste and odor?

A8: Iron removal significantly improves water taste, eliminating metallic or rusty flavors.

Q9: How to choose the right model?

A9: Selection depends on flow rate, iron concentration, and application type — our engineers provide tailored recommendations.

Q10: Where can I buy or customize Iron Removal Equipment?

A10: You can directly contact Qingdao EPIC Mining Machinery Co., Ltd. for custom solutions and quotations.

5. About Qingdao EPIC Mining Machinery Co., Ltd. & Contact Us

Qingdao EPIC Mining Machinery Co., Ltd. is a professional manufacturer specializing in water and mineral purification systems. With decades of technical experience, the company has developed advanced Iron Removal Equipment that meets both domestic and international quality standards. Each system is engineered to deliver high efficiency, low maintenance, and sustainable performance across water treatment, mining, metallurgy, and chemical industries.

Why Choose EPIC?

-

20 years of expertise in mining and water treatment technology

-

Strong R&D team and customized engineering solutions

-

International certifications and strict quality control systems

-

Global service network and responsive technical support

By continuously innovating in the field of purification machinery, Qingdao EPIC Mining Machinery Co., Ltd. has earned a trusted reputation for delivering reliable, energy-efficient, and environmentally responsible Iron Removal Equipment.

Ready to improve your water and mineral purification process?

Contact us today to learn more about custom Iron Removal Equipment solutions designed to meet your exact operational needs.